Vayu Aircraft

I led the development of a medical delivery drone designed to help those in the direst of need.

How This All Started

Early concept illustration I created for a Vayu prototype.

In 2014 I left Twitter to look for opportunities in the product and design space. I was looking for projects that, like Twitter, could be used by marginalized or at-risk populations to measurably improve their quality of life. A good friend of mine from Twitter, e, had recently invested in an aviation company with a mystical name — Vayu. After speaking with Daniel Pepper, the founder, I traveled to Michigan to help them produce marketing material and contribute to the design of an eventual app. I believed in this mission deeply, and agreed to work on an expense and equity only basis.

Vayu's mission: Build a robotic aircraft to deliver urgent and lifesaving medical goods to the almost 1 billion people around the world who do not have access to all-weather, all season roads.

Video

Filmed B-Roll with a BMPCC on a doorway dolly. Lenses include Tokina, Sigma and Canon.

Filmed with Sony FS7, and BMPCC. Graded using Lumetri with no LUTs.

Filmed with a iPhone 6S, Moment Wide lens for certain shots, using Filmic Pro and ScopeFlare App.

Beginning in June of 2015, I regularly traveled to Vayu's hangar/office in Michigan to help with the development and marketing of their aircraft.

Unique in it's design, the "P" Generation prototype employed 4 lifting fans embedded into a flying wing design. This would allow the UAV to "lift-off" like a helicopter – then transition to airplane – giving it incredible range and payload capacity.

The aircraft was made mostly from molded carbon fiber, and had been under development since Vayu's beginning. The founder felt the aircraft was nearing completion, and my first task should be to produce a product demo video of the aircraft. Over the next two months I traveled back and forth to Michigan filming the fabrication process, test flights, and interviews.

However, as time passed it became clearer to me that the aircraft was not as far along as hoped, and still had a significant period of design and testing before it would be ready for a public demonstration. With this realization, I discussed refocusing my time at Vayu on other tasks more closely related to the development of the product, and raising of capital investment. The P Generation aircraft was cancelled before we could do a public demo video, but that cancellation lead to my greater involvement in the design of the aircraft, which I document later.

All the footage I shot without a crew, using a Sony PXW-FS7, Blackmagic Pocket Cinema Camera, or iPhone. For some of the moving shots I used a simple Mathews doorway dolly which I operated myself.

Renderings

As a way to help Vayu's investors visualize the future of our product, I regularly created photographic renderings of the P Generation aircraft (which I named, "The Courier"). These renderings translated into imagery what Vayu's engineers and advisers were devising in CAD and code.

These images were created using Solidworks .STEP files received from the engineers. From there, I would convert the model into NURBS, texture, shade, light, animate, and pose the models in 3dsMax. I would then render them using vRay, and composite them in Photoshop.

Rescue supply concept.

Propulsion details for the Courier aircraft.

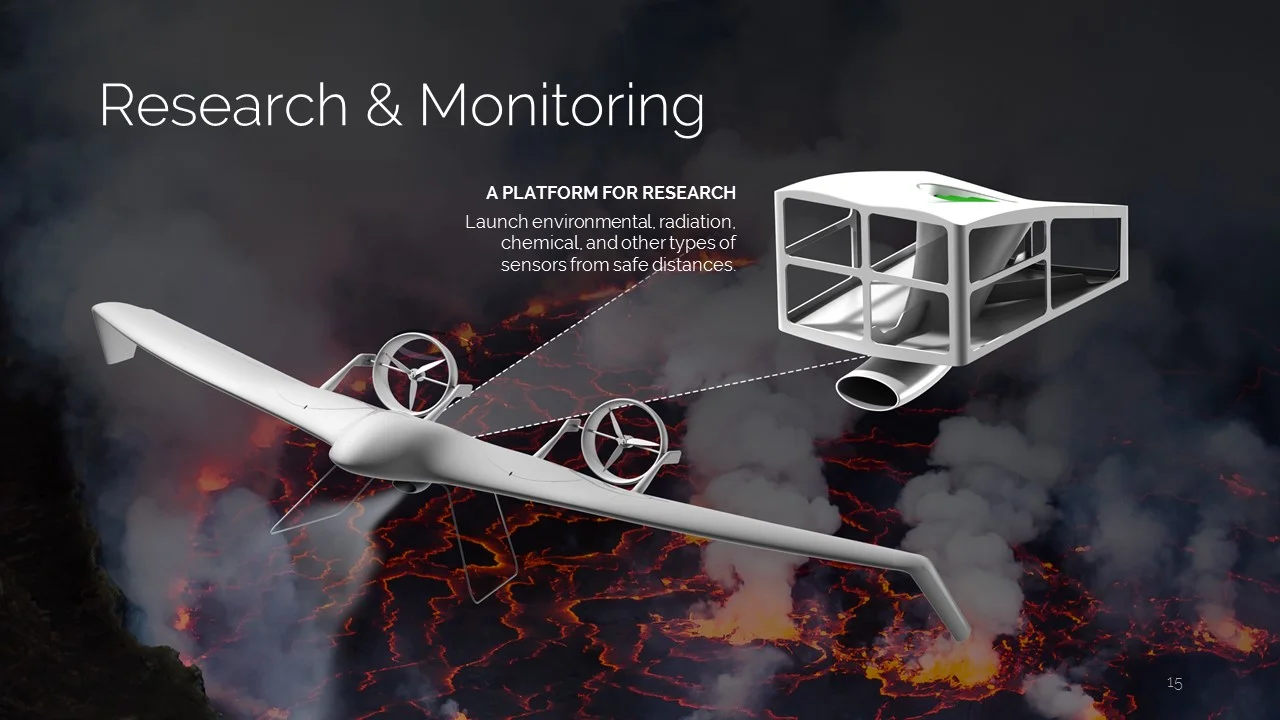

As part of my expanding role at Vayu, I also fully concepted and designed multiple cargo bay configurations that to fit in the central payload area of the Courier aircraft. The idea of being able to re-purpose the aircraft for missions beyond medical aid was something I championed early-on, and also integrated into the business development and investment language that would follow.

Context renderings of both the aircraft with interchangeable payload, and operating environment.

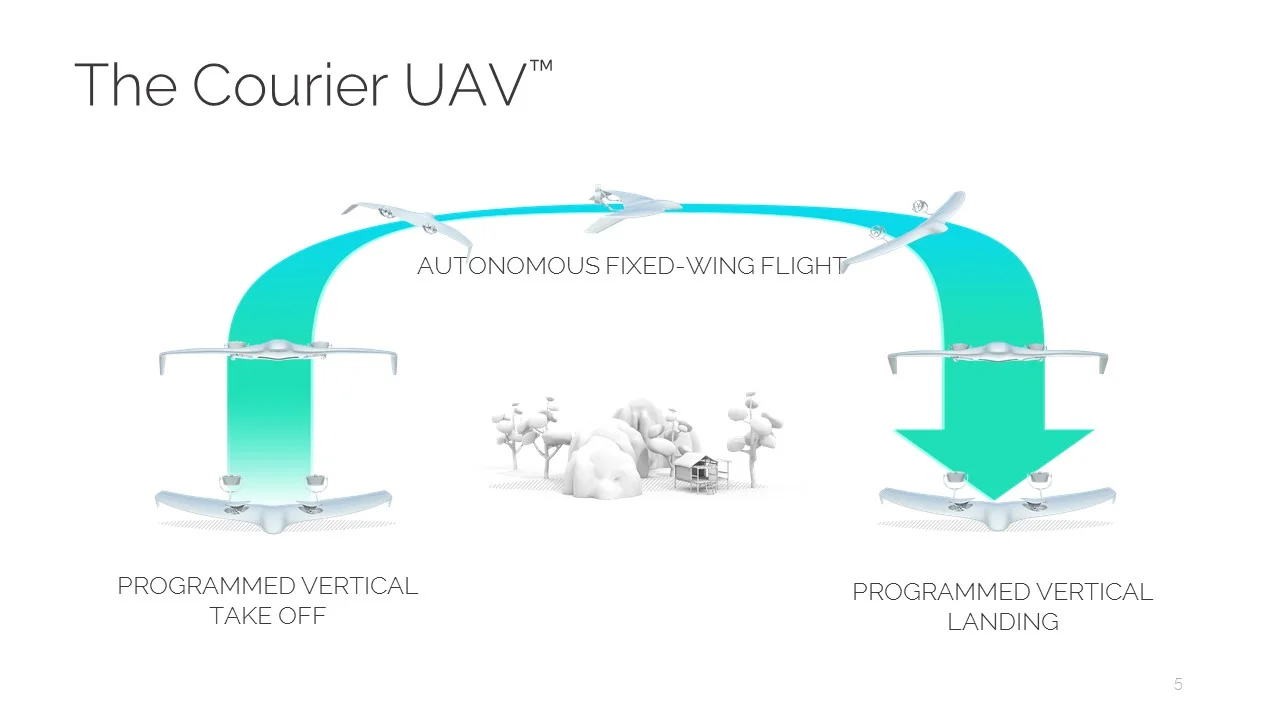

Illustration to demonstrate the VTOL (Vertical-Takeoff-or-Landing) capabilities of the Courier.

Illustration showing the 5 modes of flight for the Courier: 1. Takeoff 2. Transition-to-flight 3. Forward flight 4. Transition-from-flight 5. Landing.

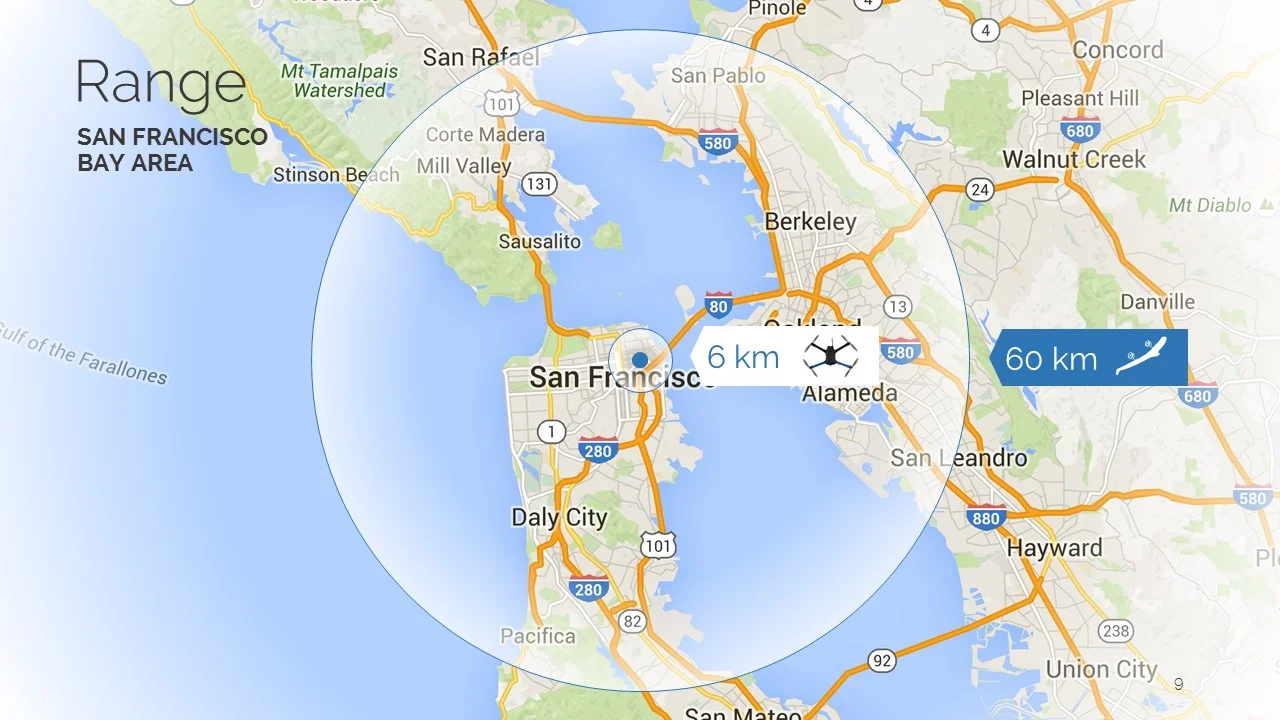

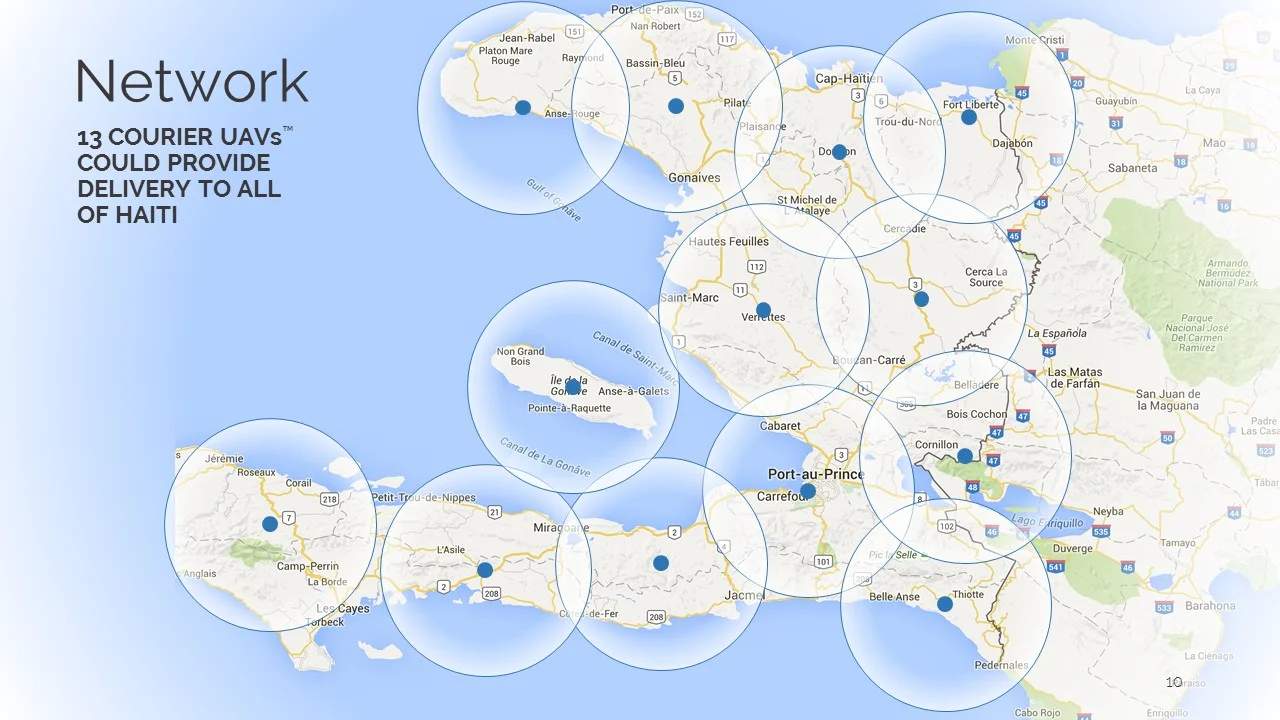

Investor Deck

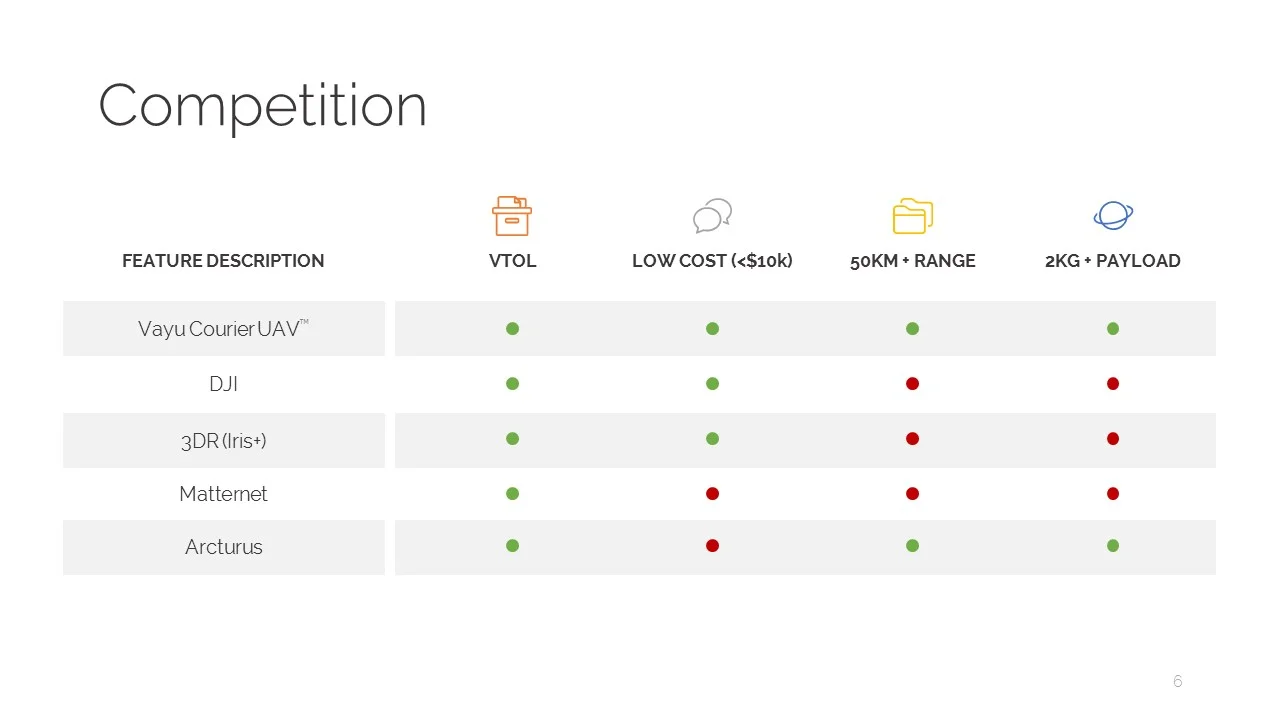

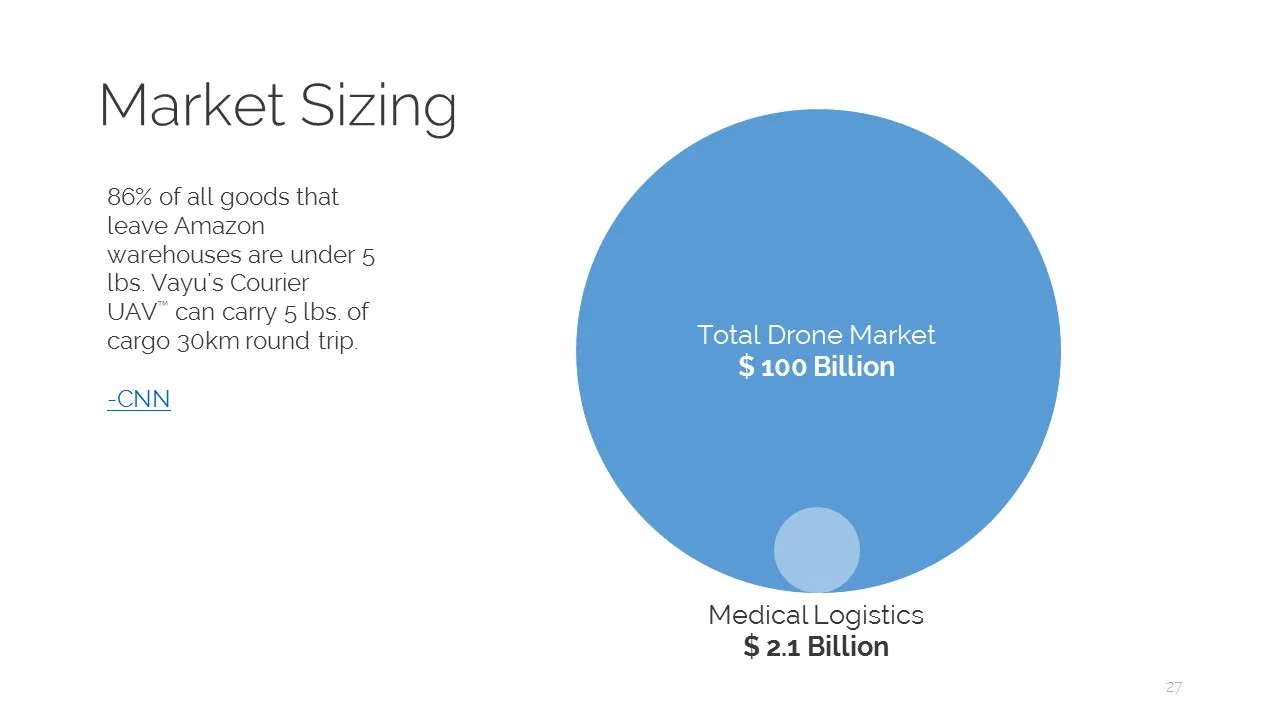

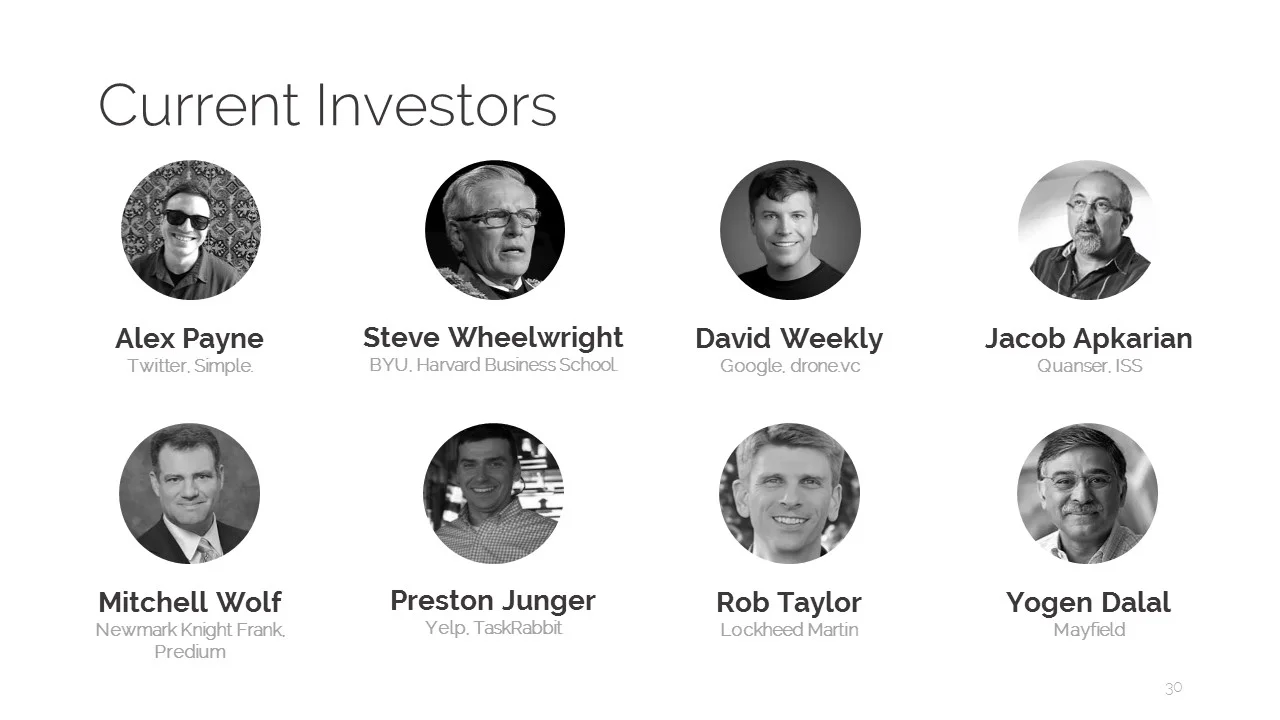

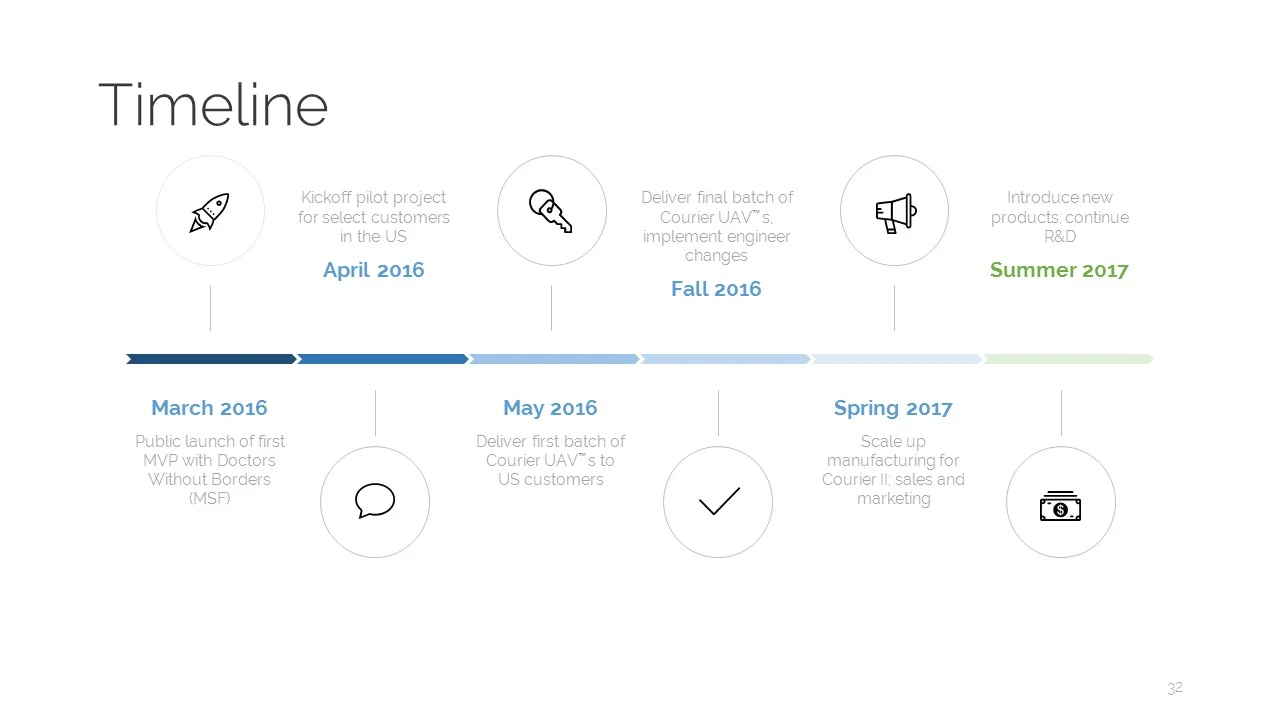

Capital investment is the lifeblood of an early stage company. The initial investment deck that the company had started with was in need of an update. We needed to better communicate the broad scope of our plans, our ambitious aircraft, and demonstrate the viability of medical delivery in the drone economy of the future.

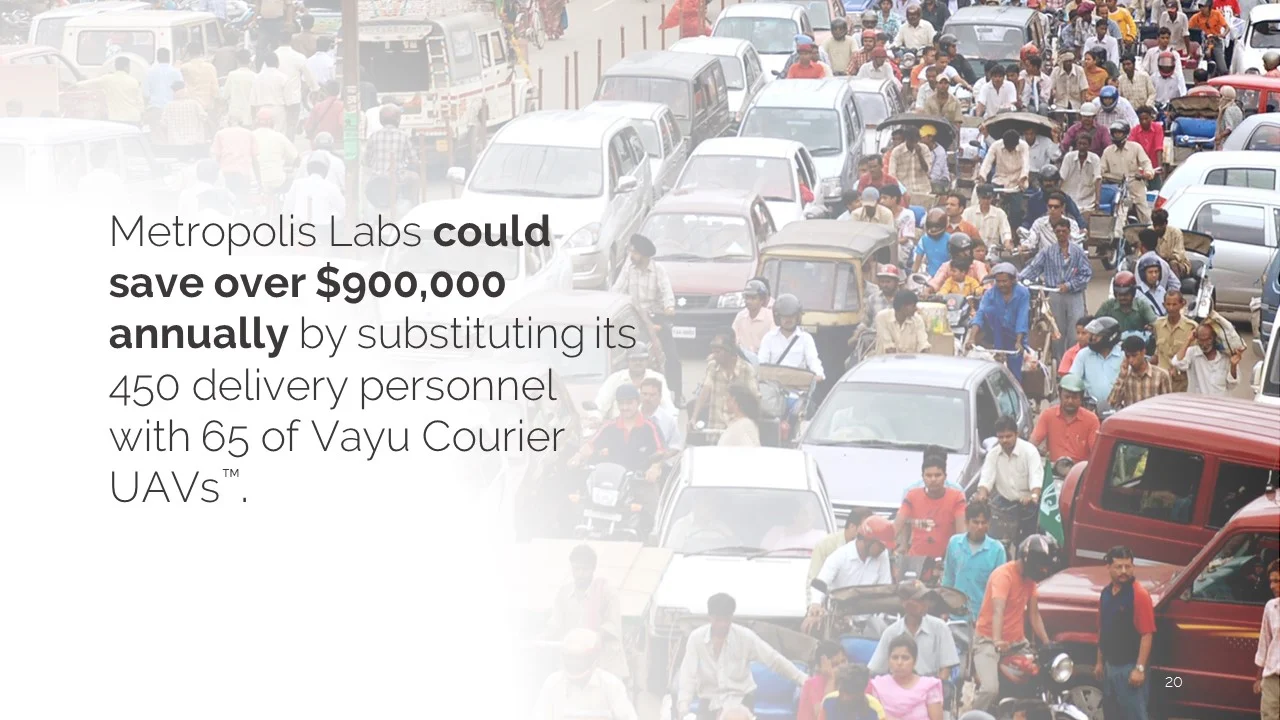

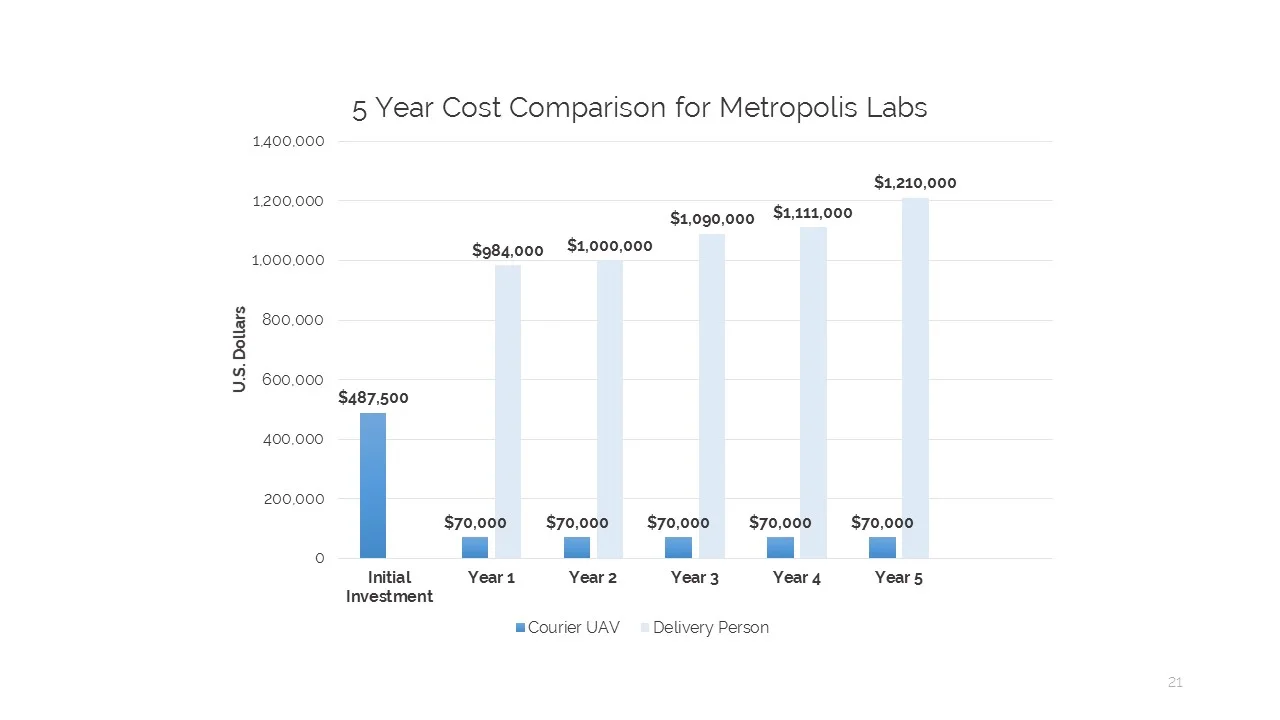

I culled through pages of early SWOT analysis, potential trial markets, and a market viability case study Vayu had researched to help investors clearly understand our mission and the potential of the market.

I made the deck in Microsoft Powerpoint, Photoshop, Sketch App, and 3dsMax. The entire deck, including App mockup was made in 6 days.

User Interface Flows

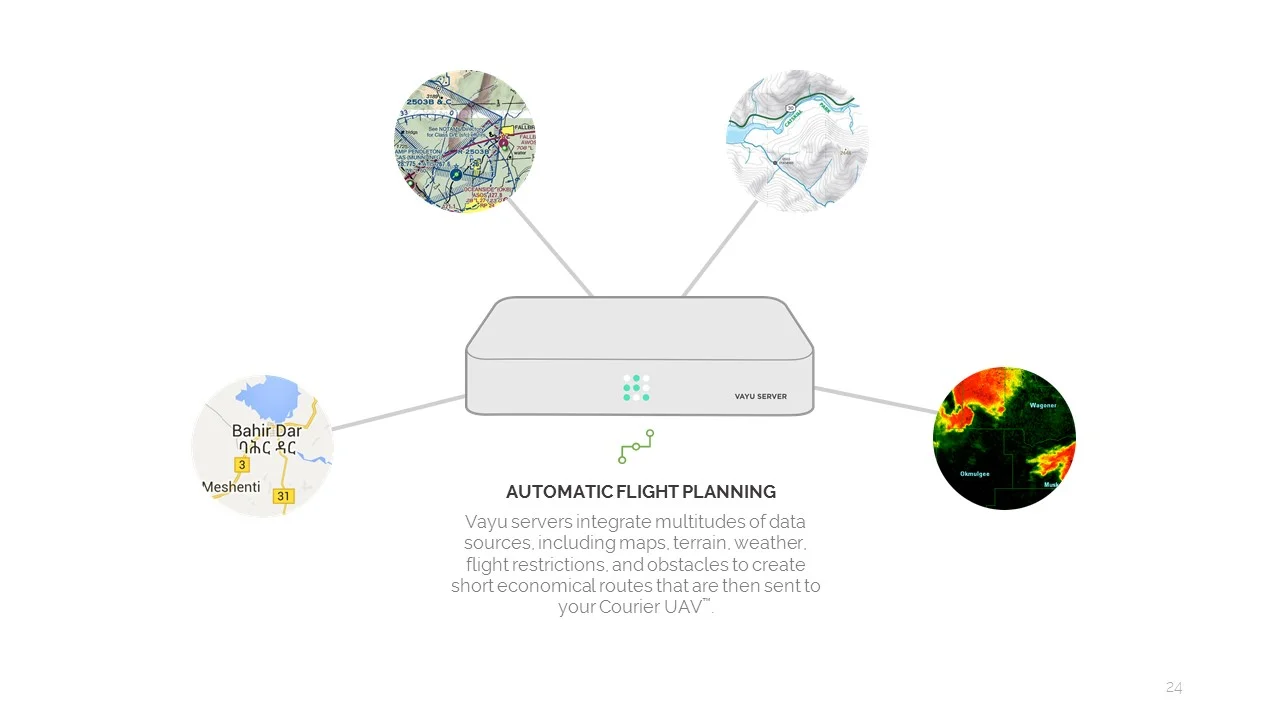

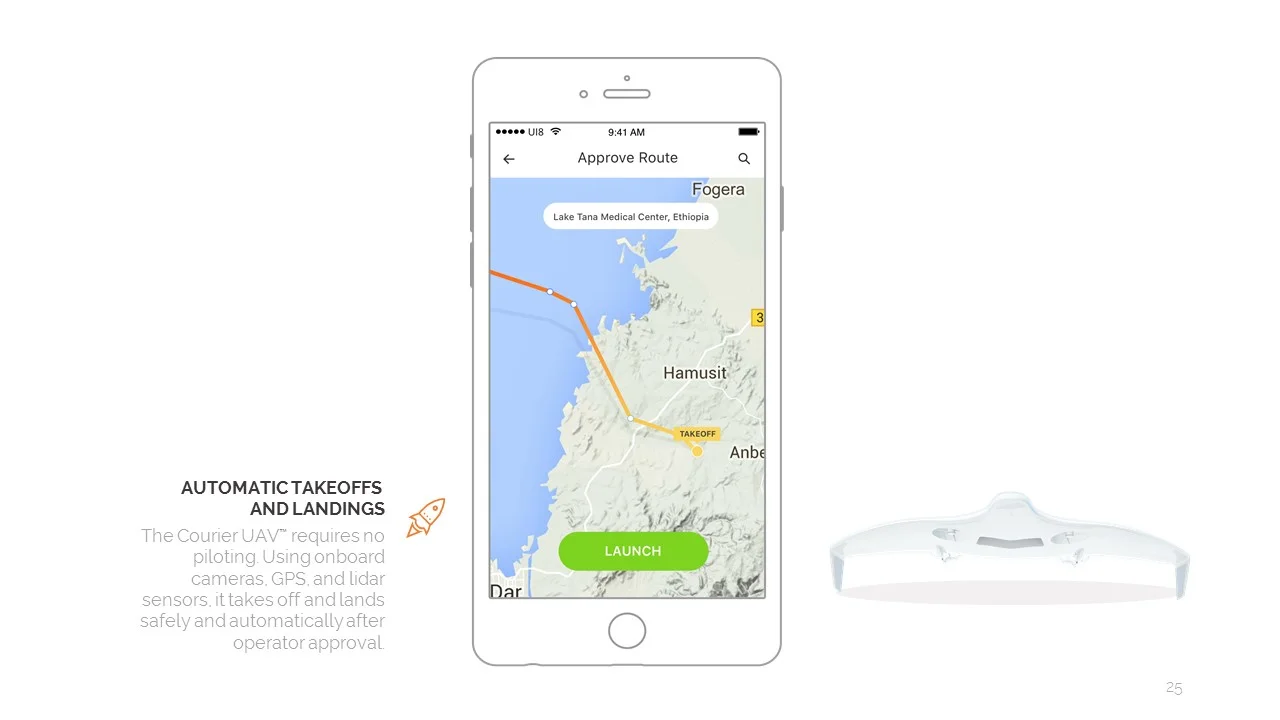

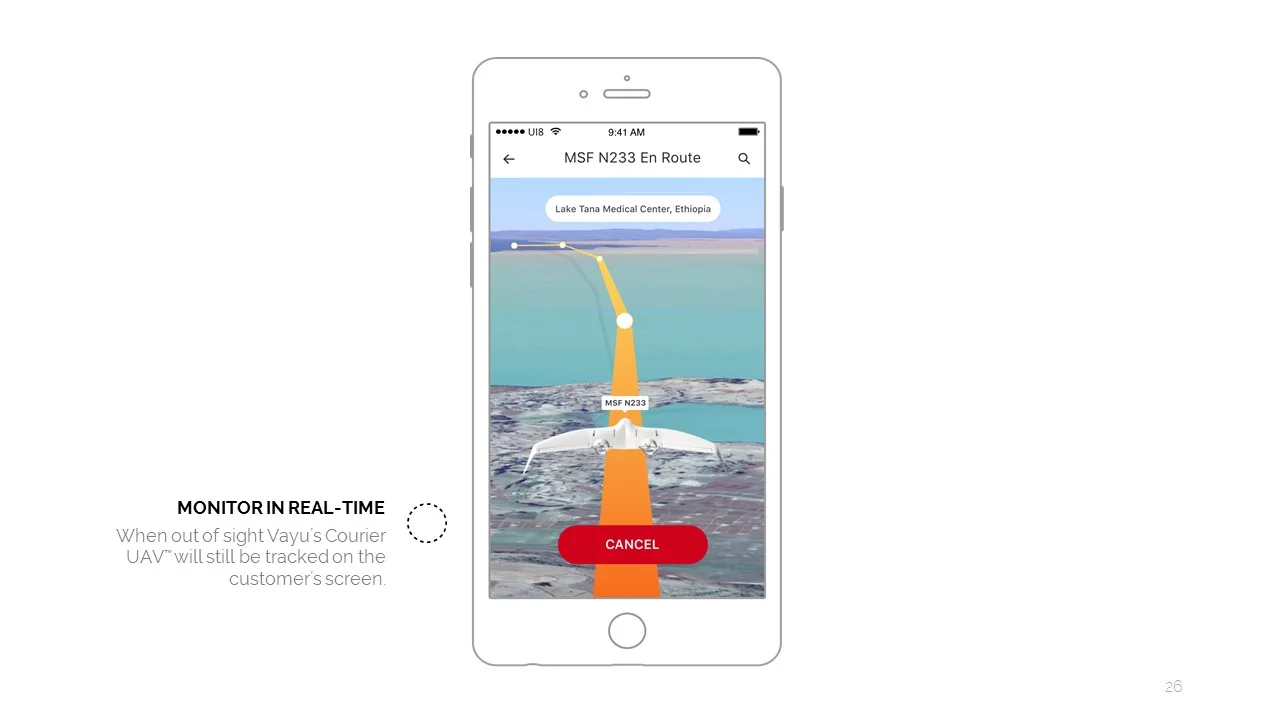

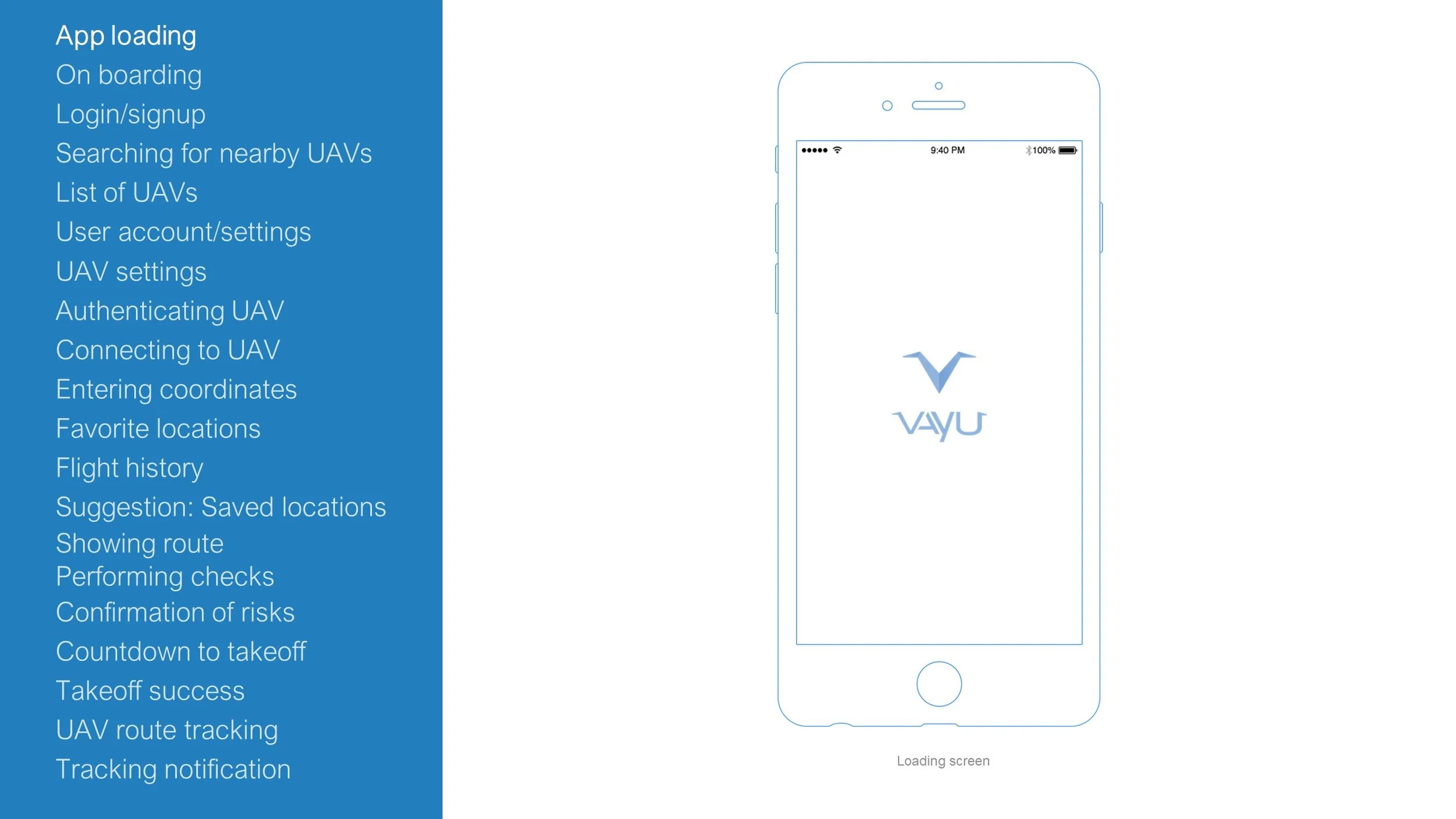

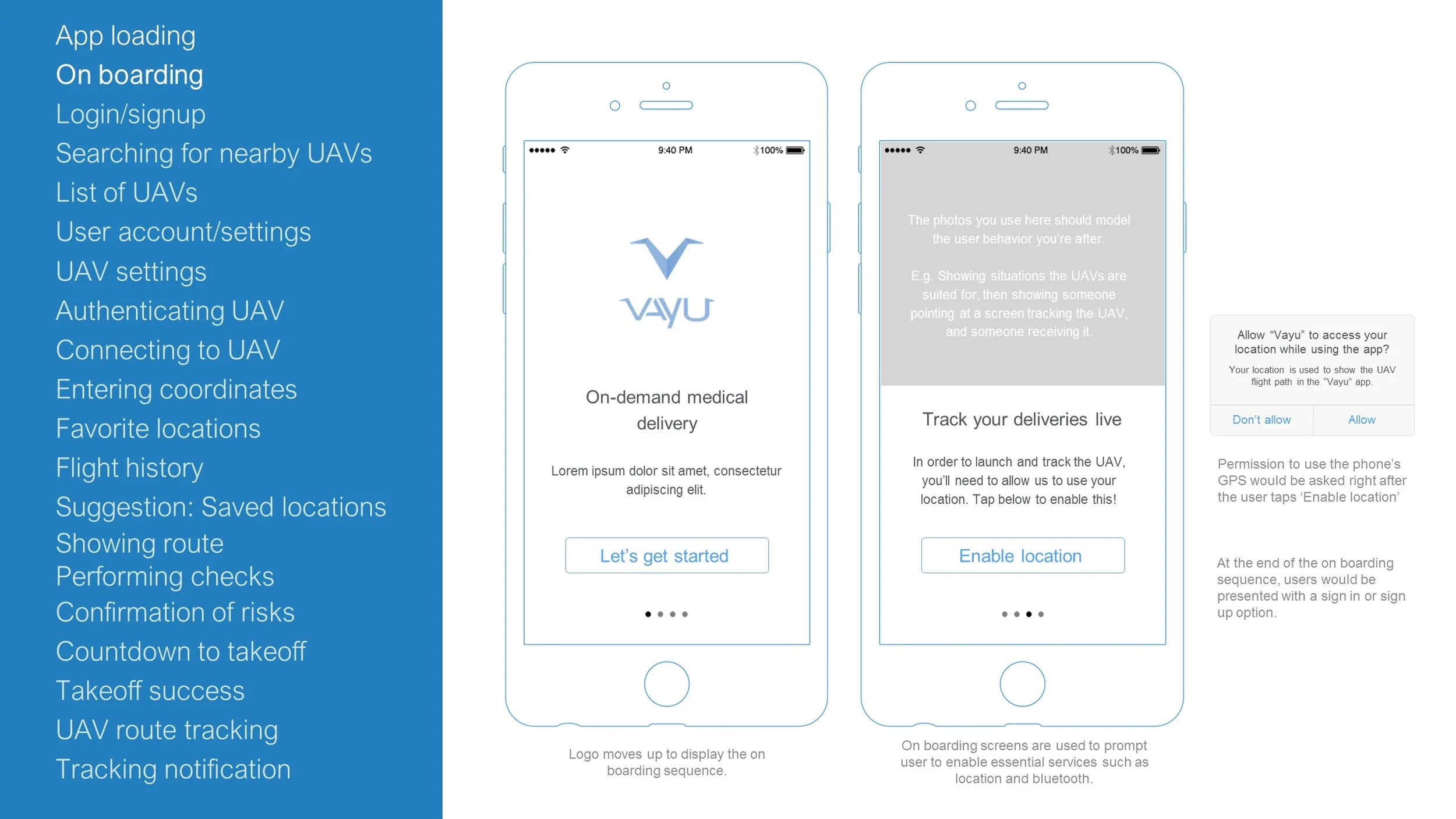

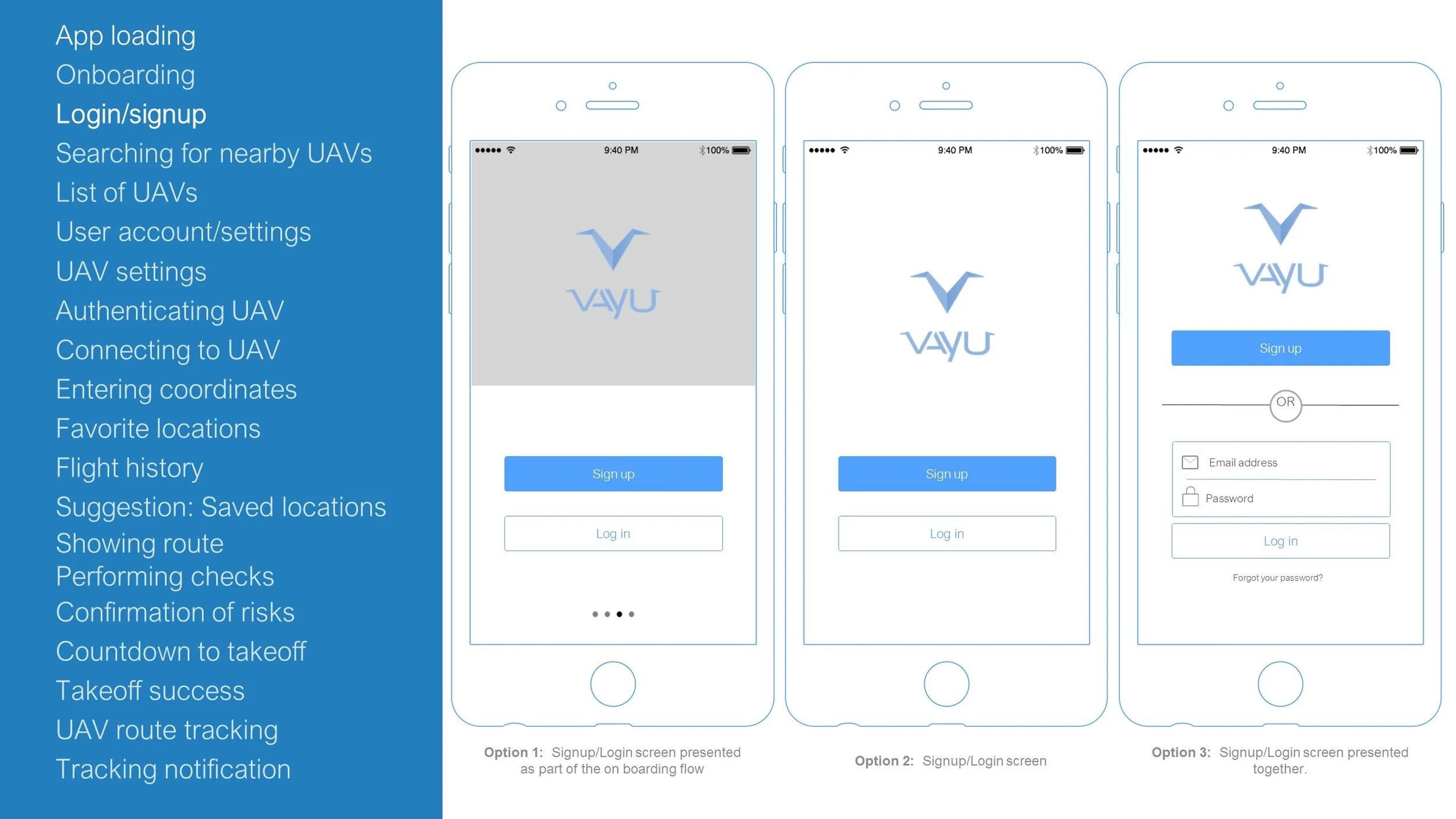

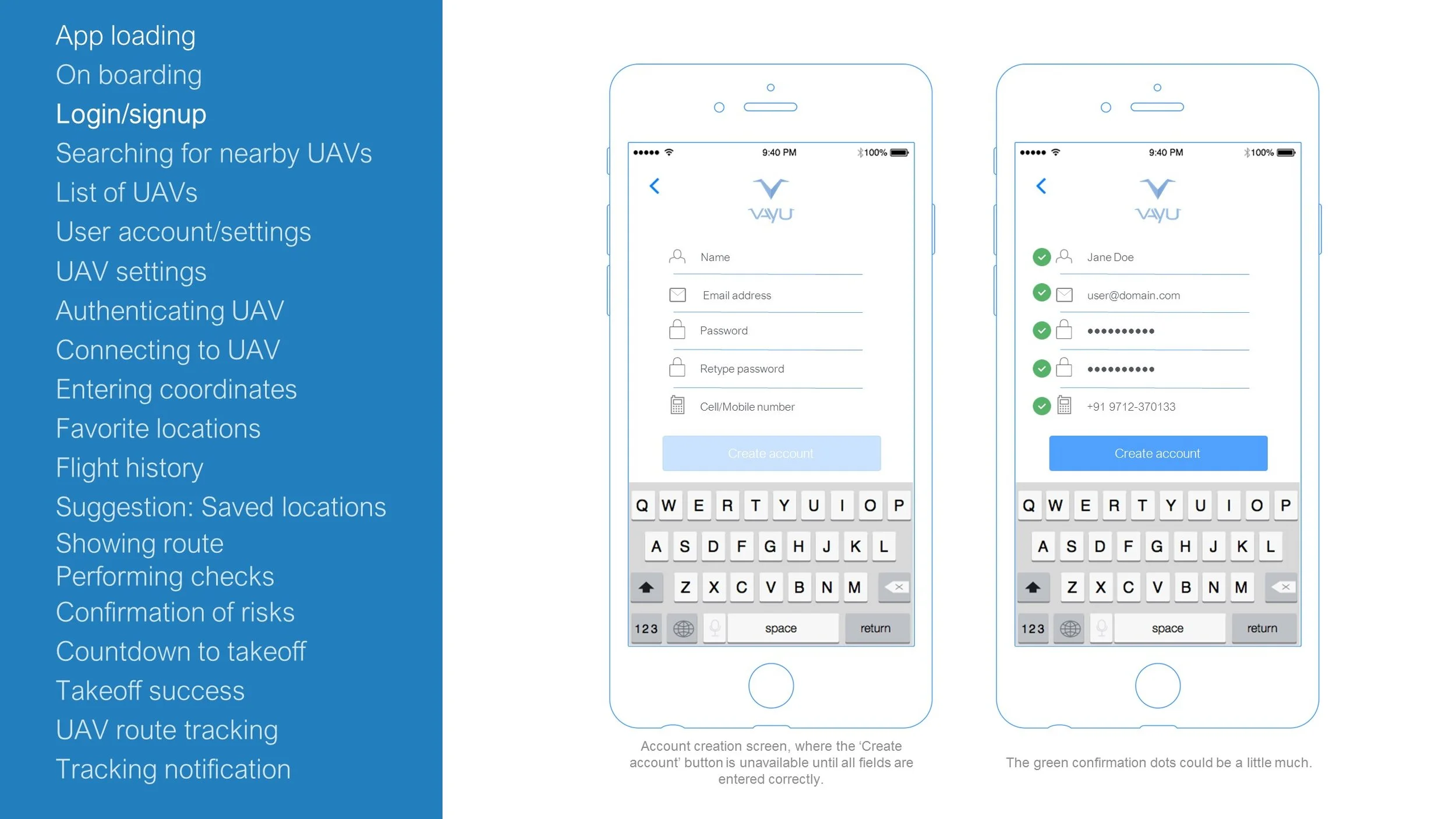

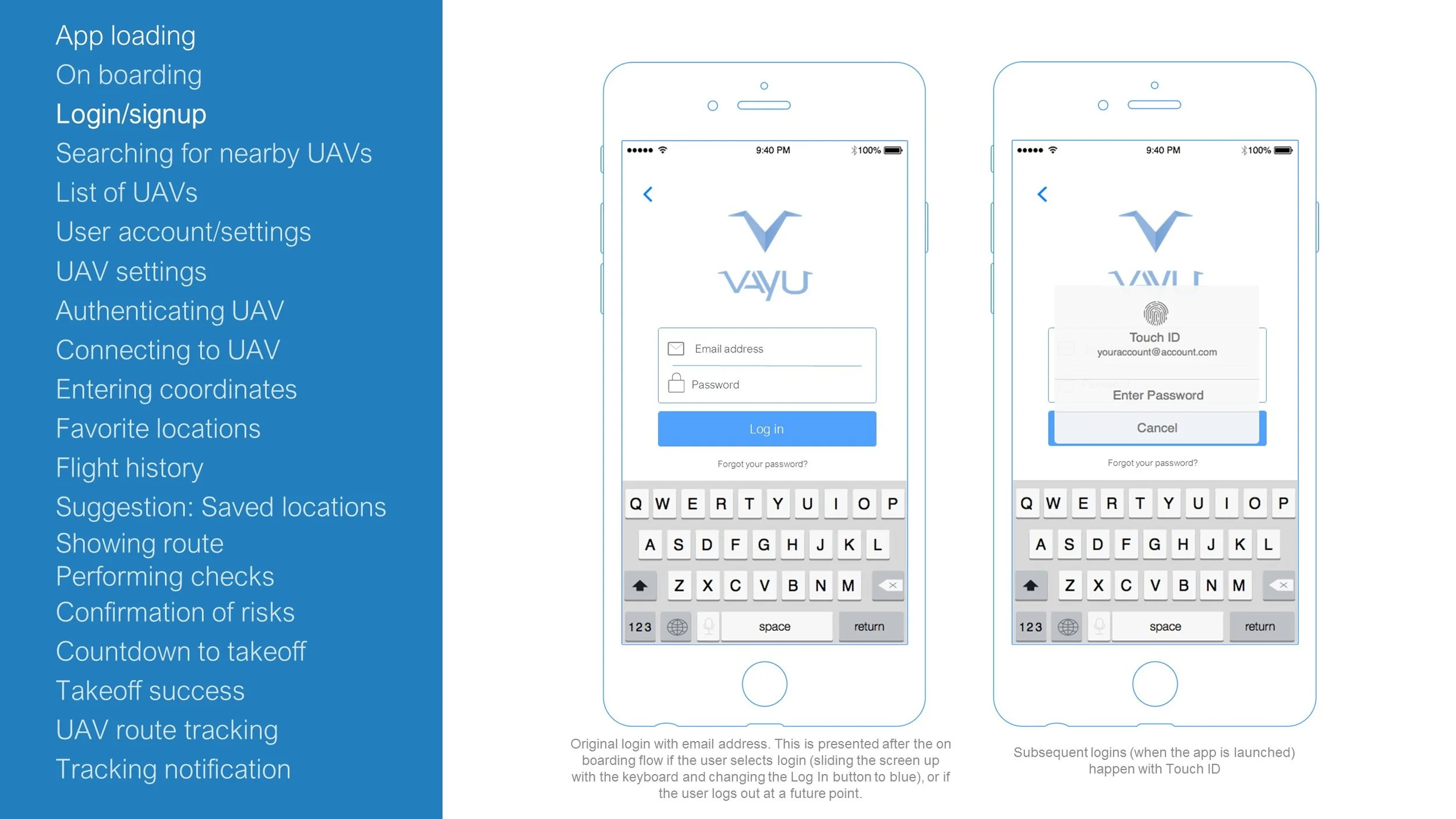

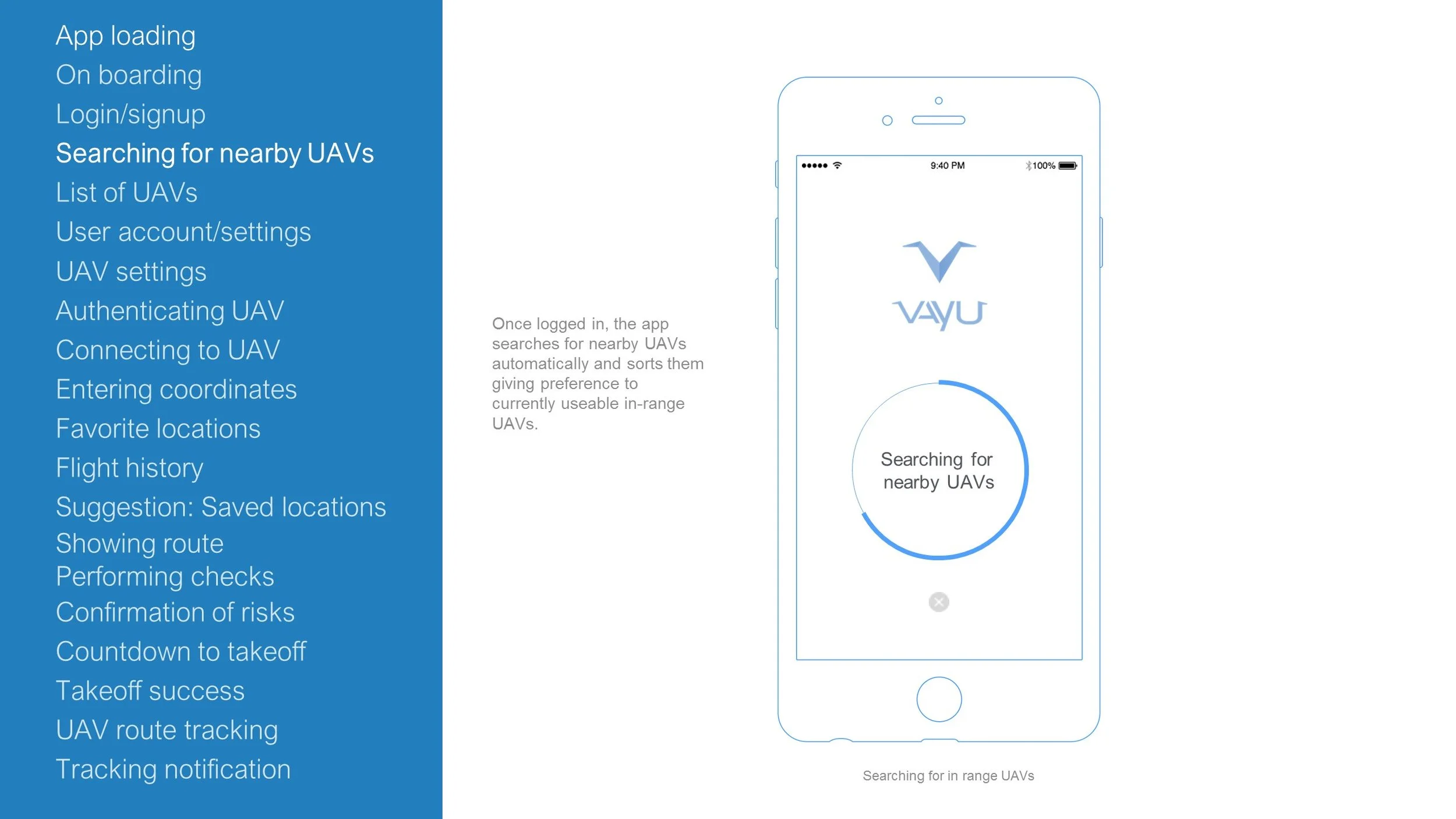

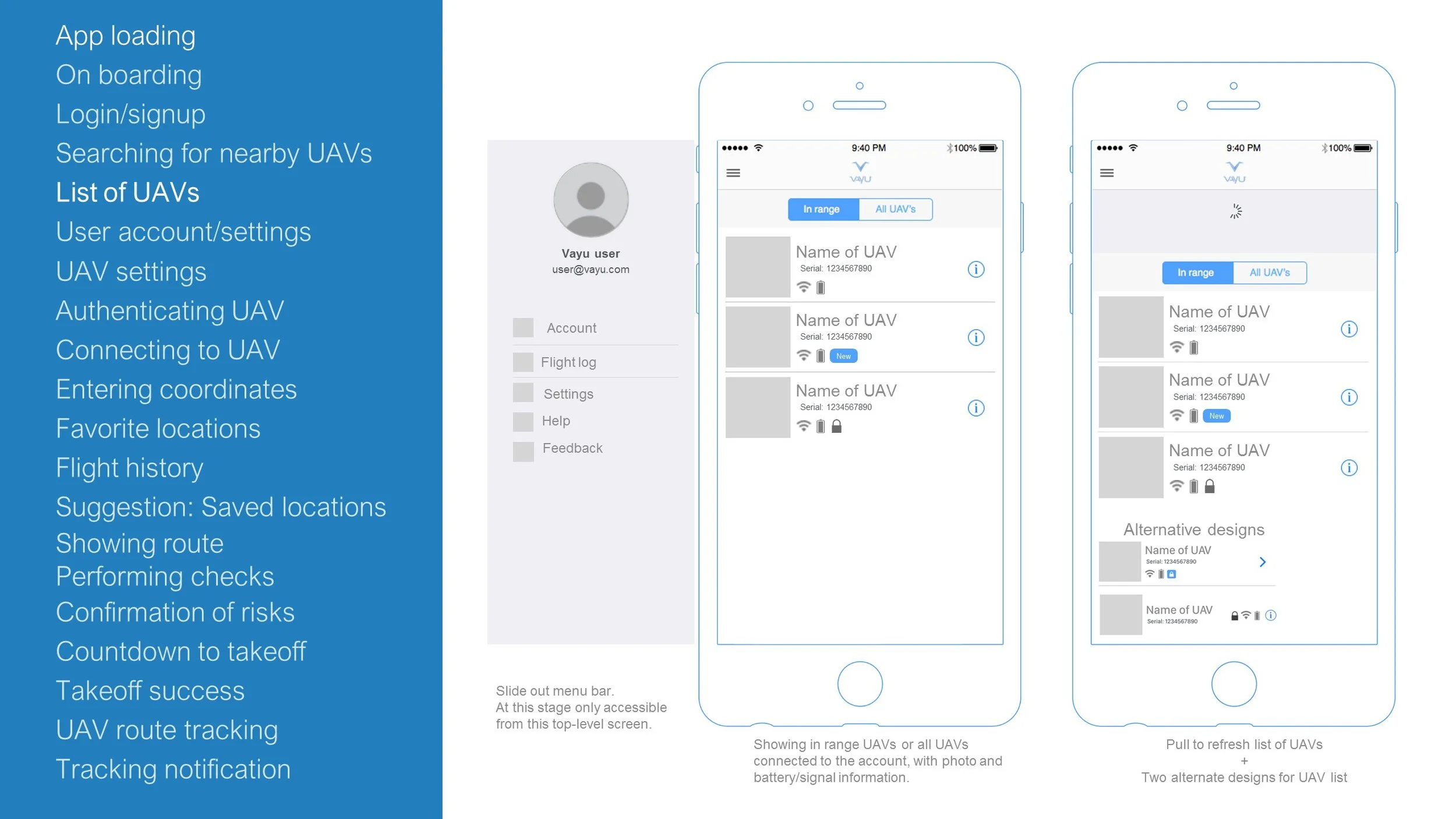

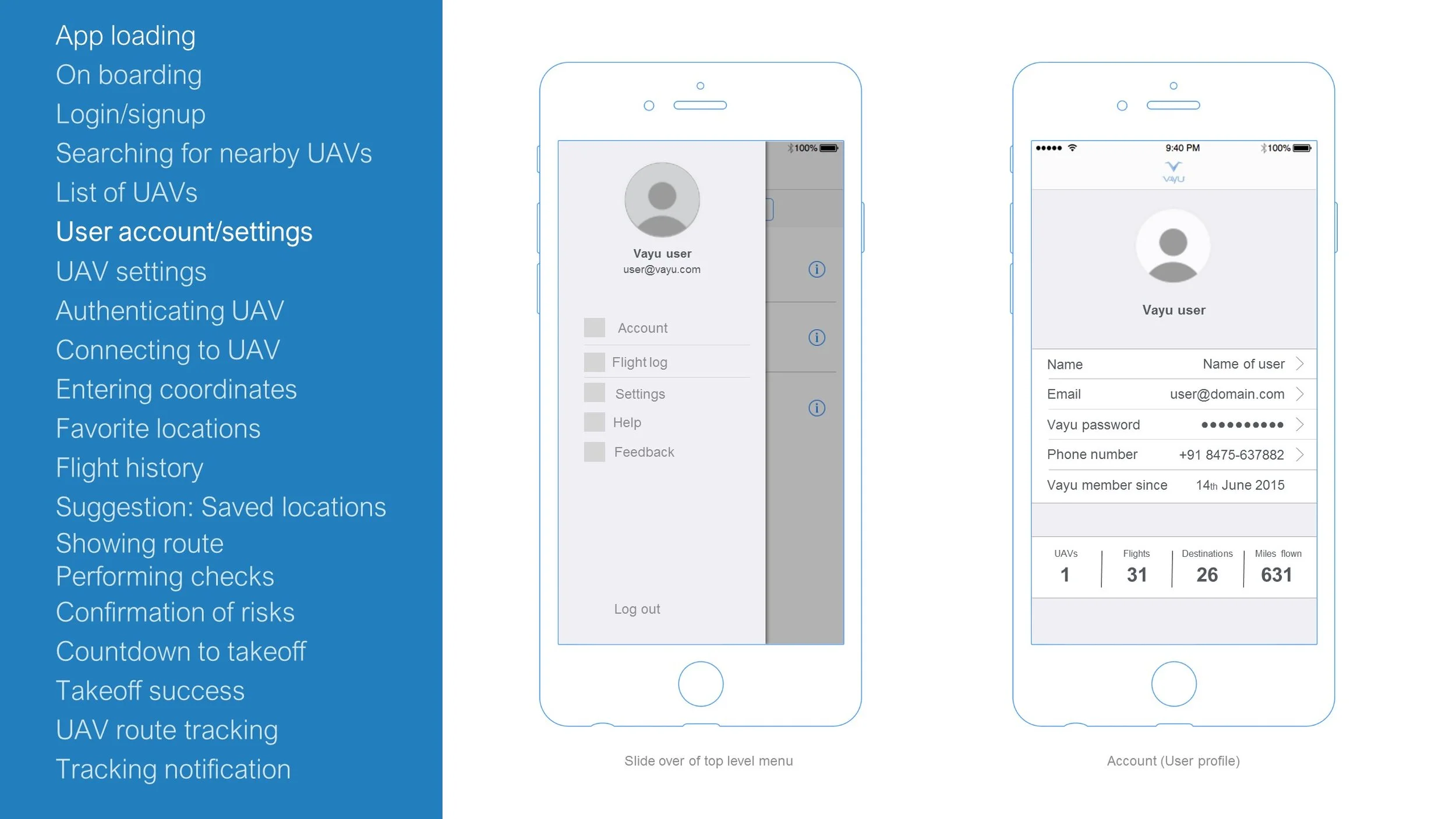

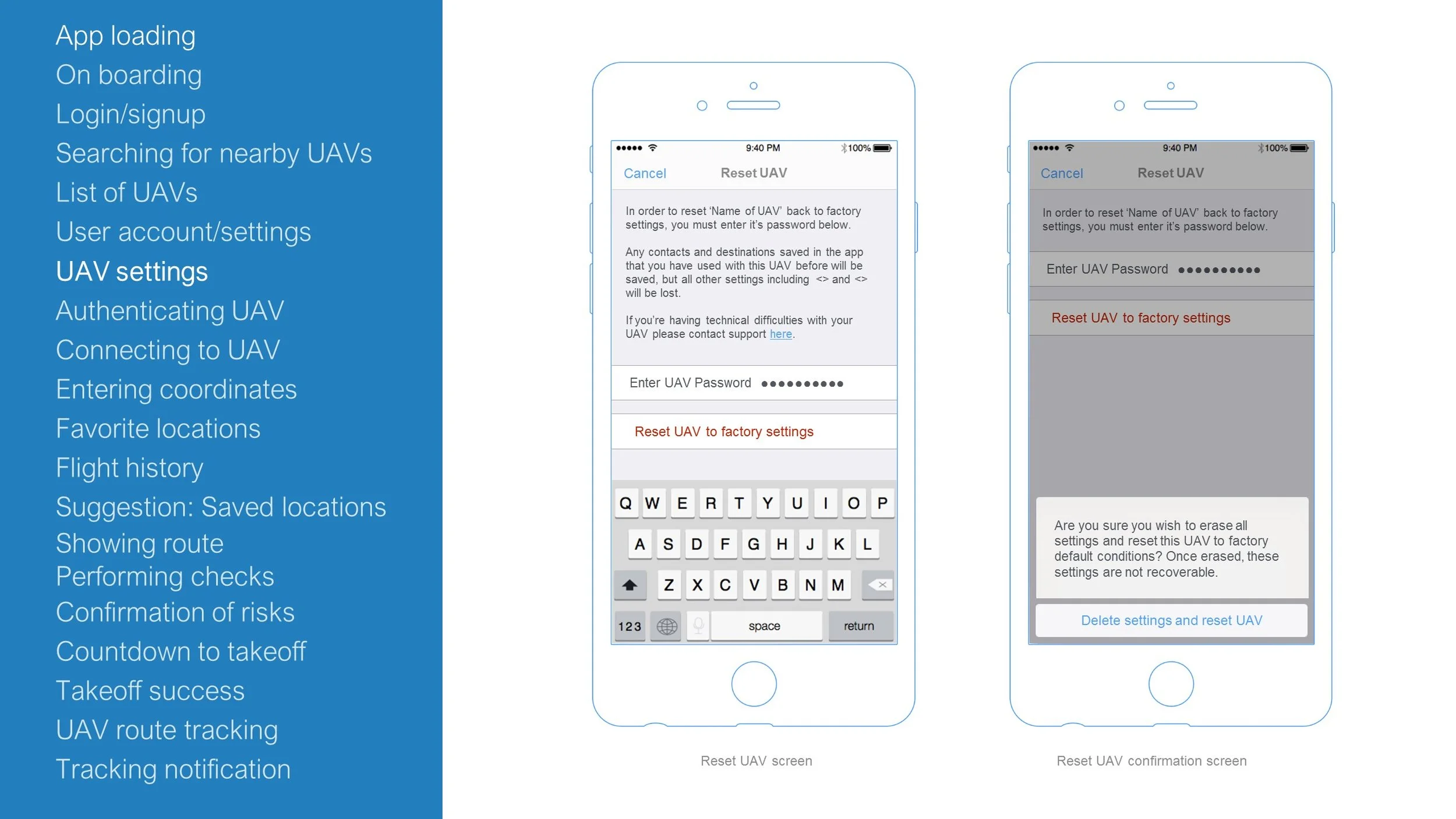

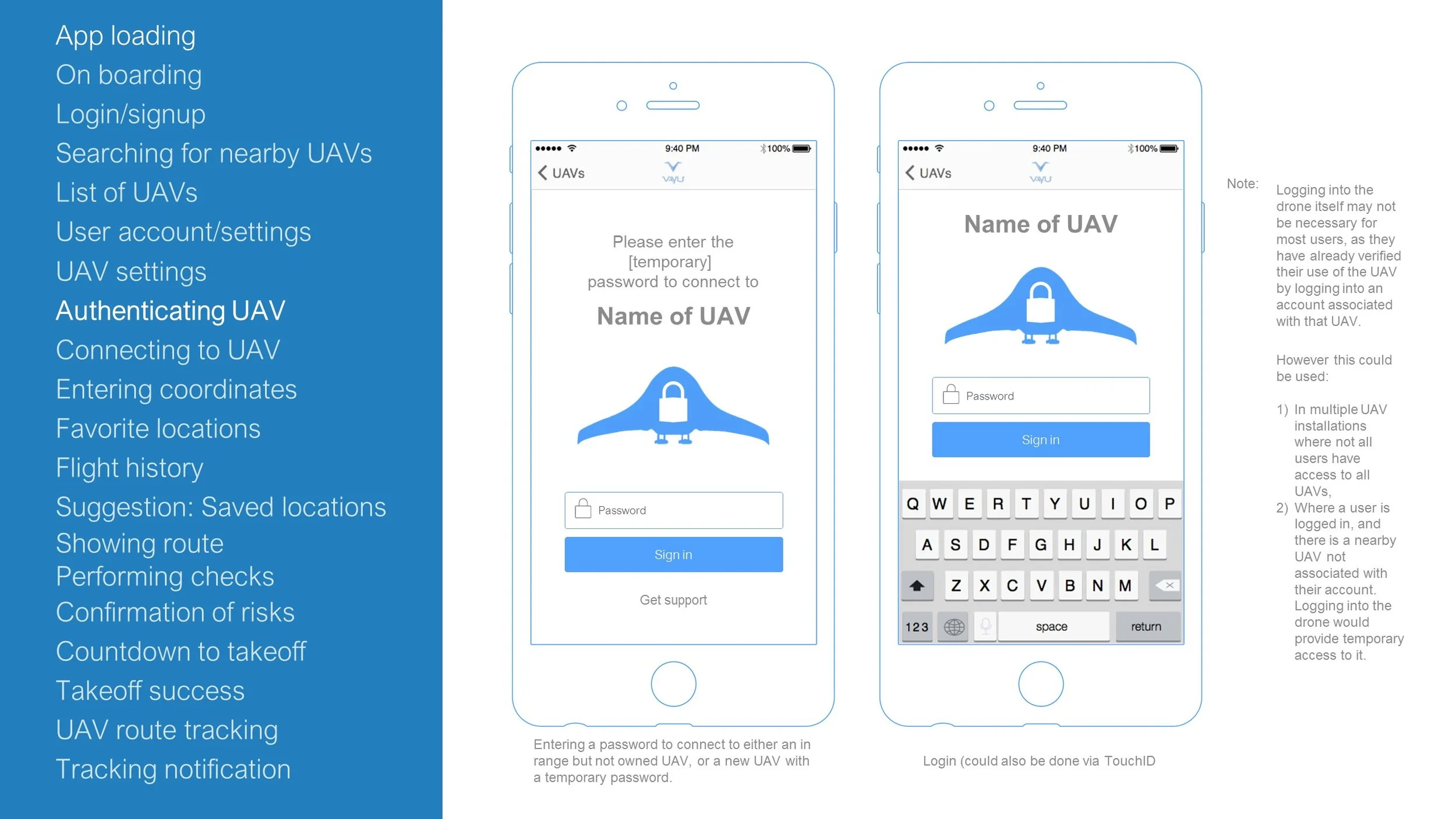

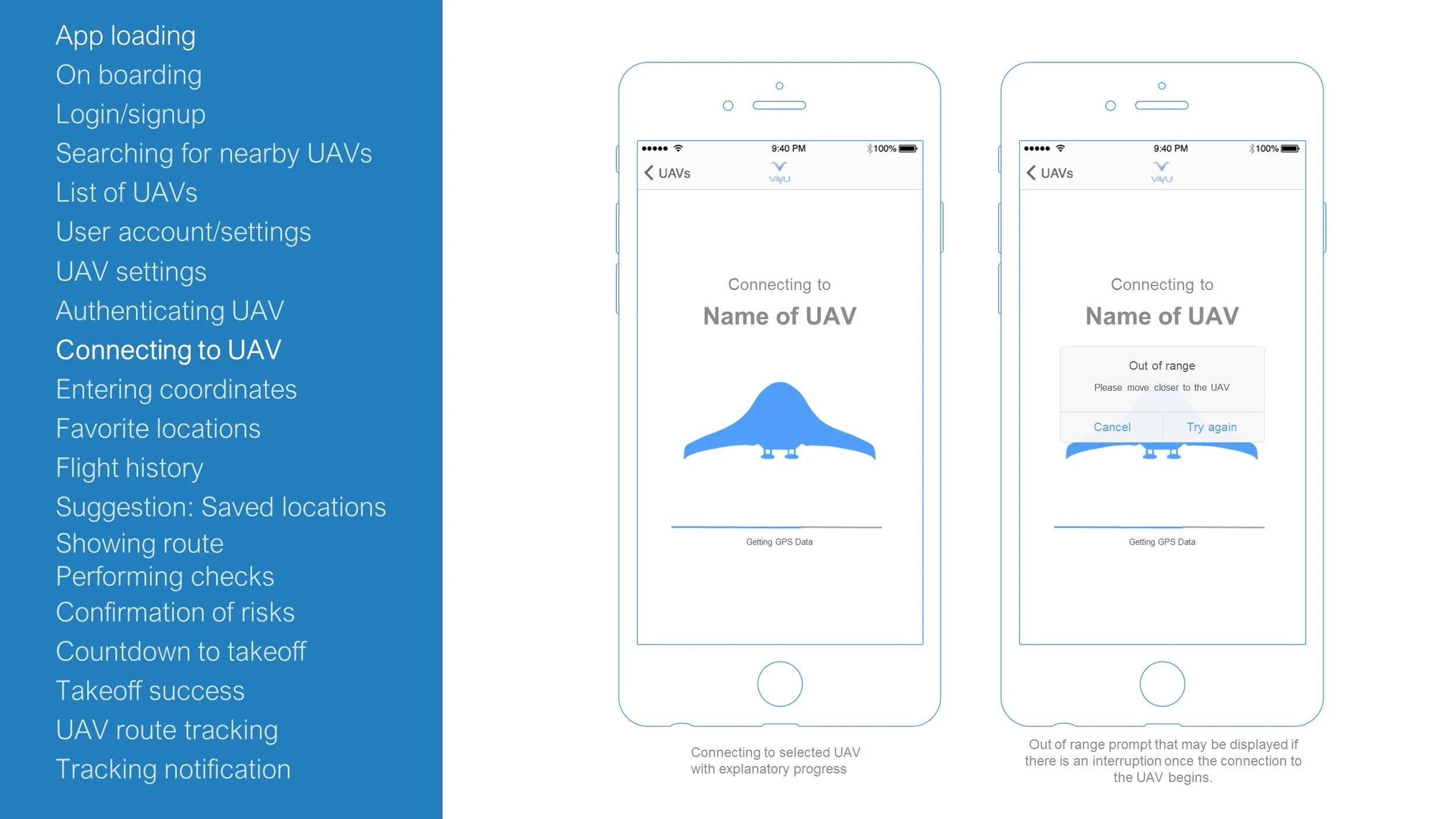

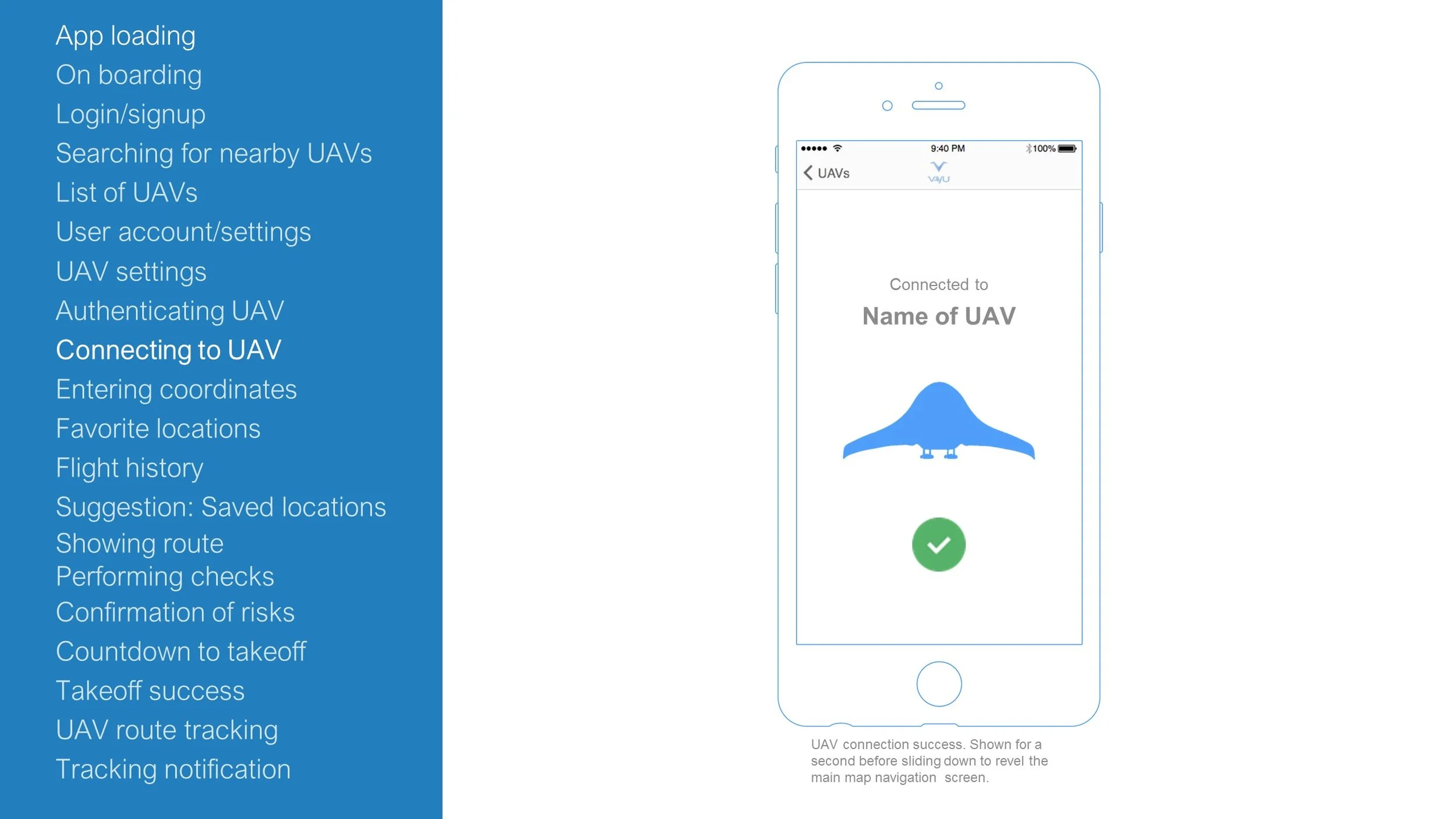

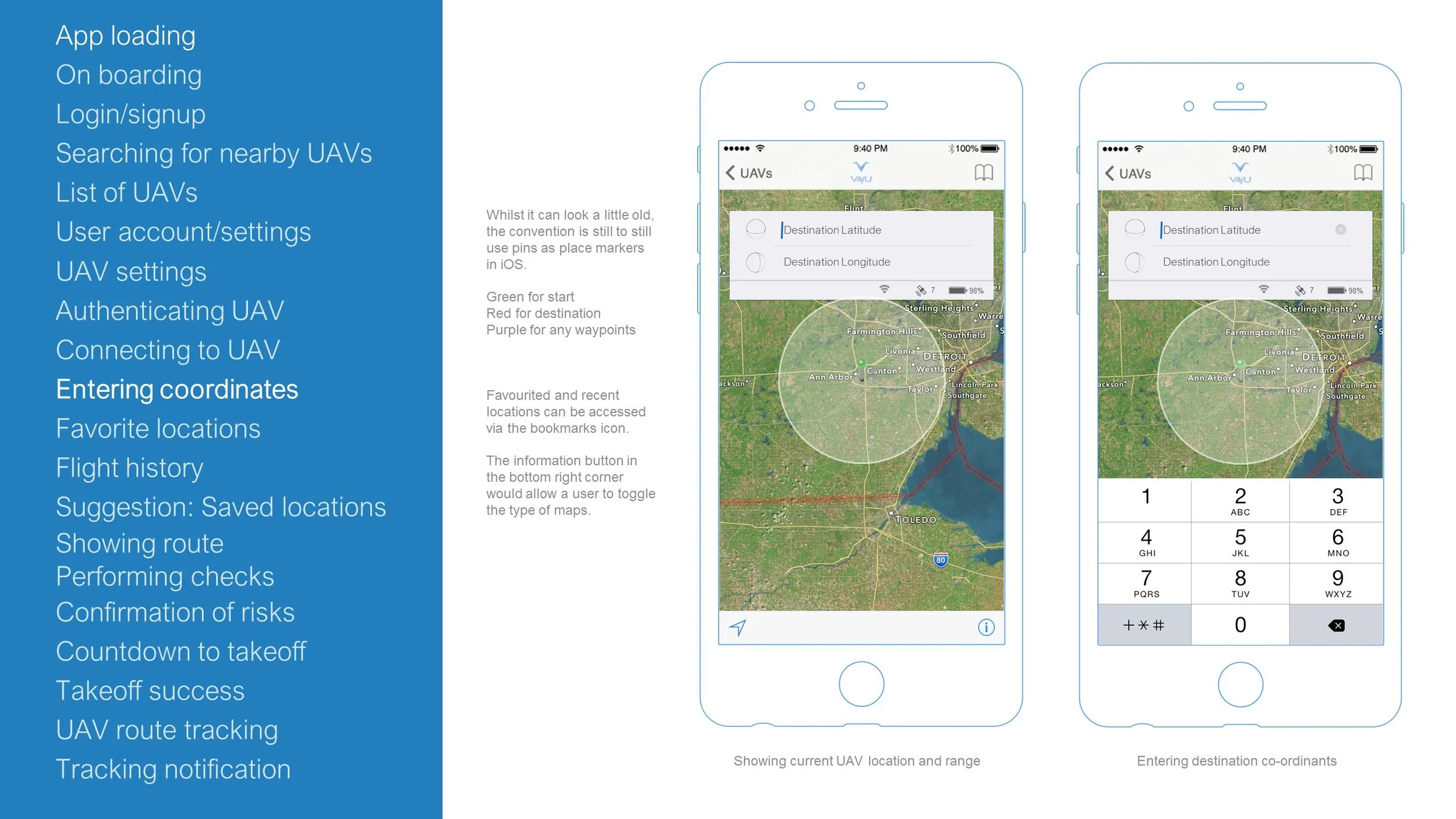

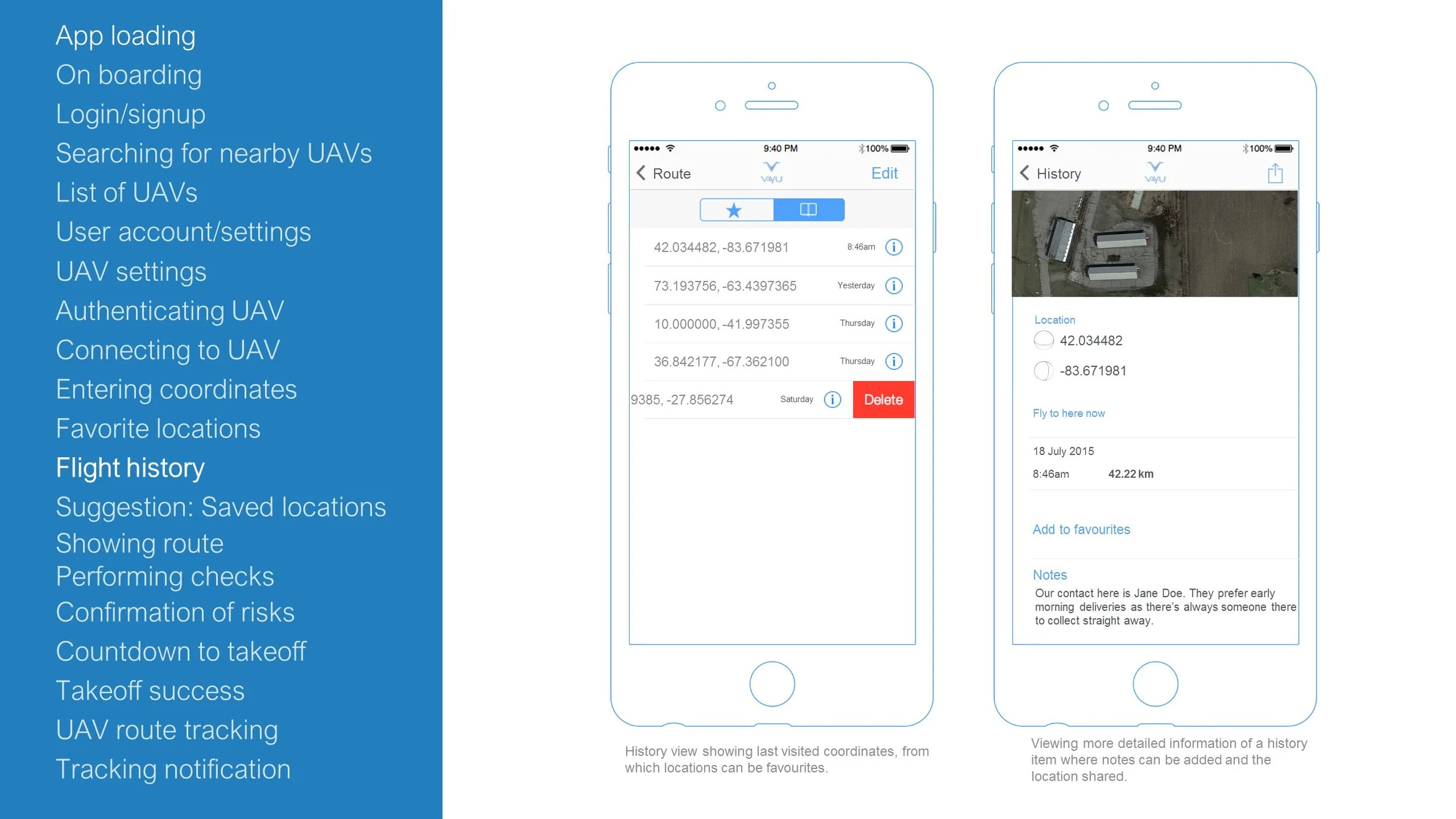

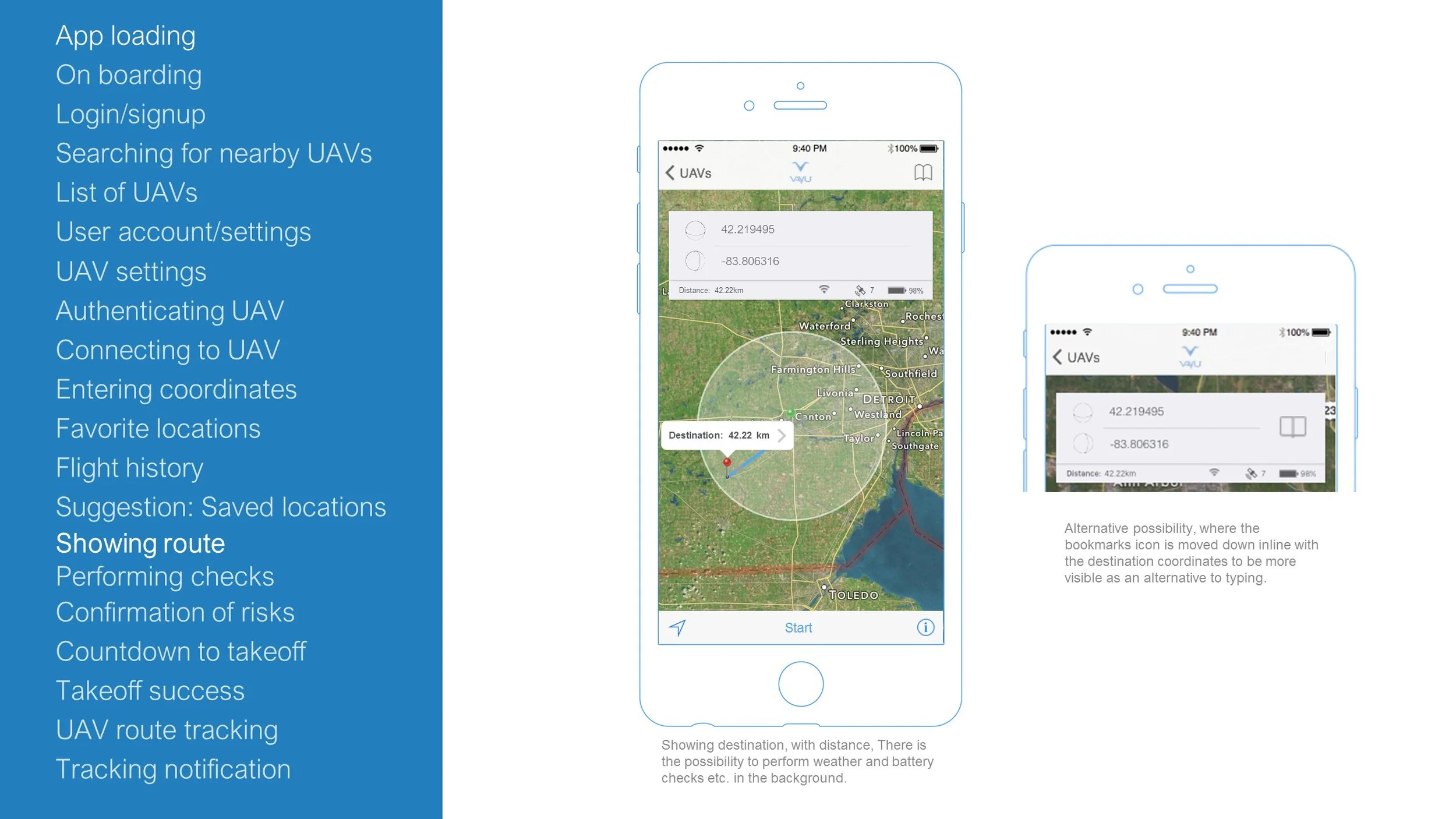

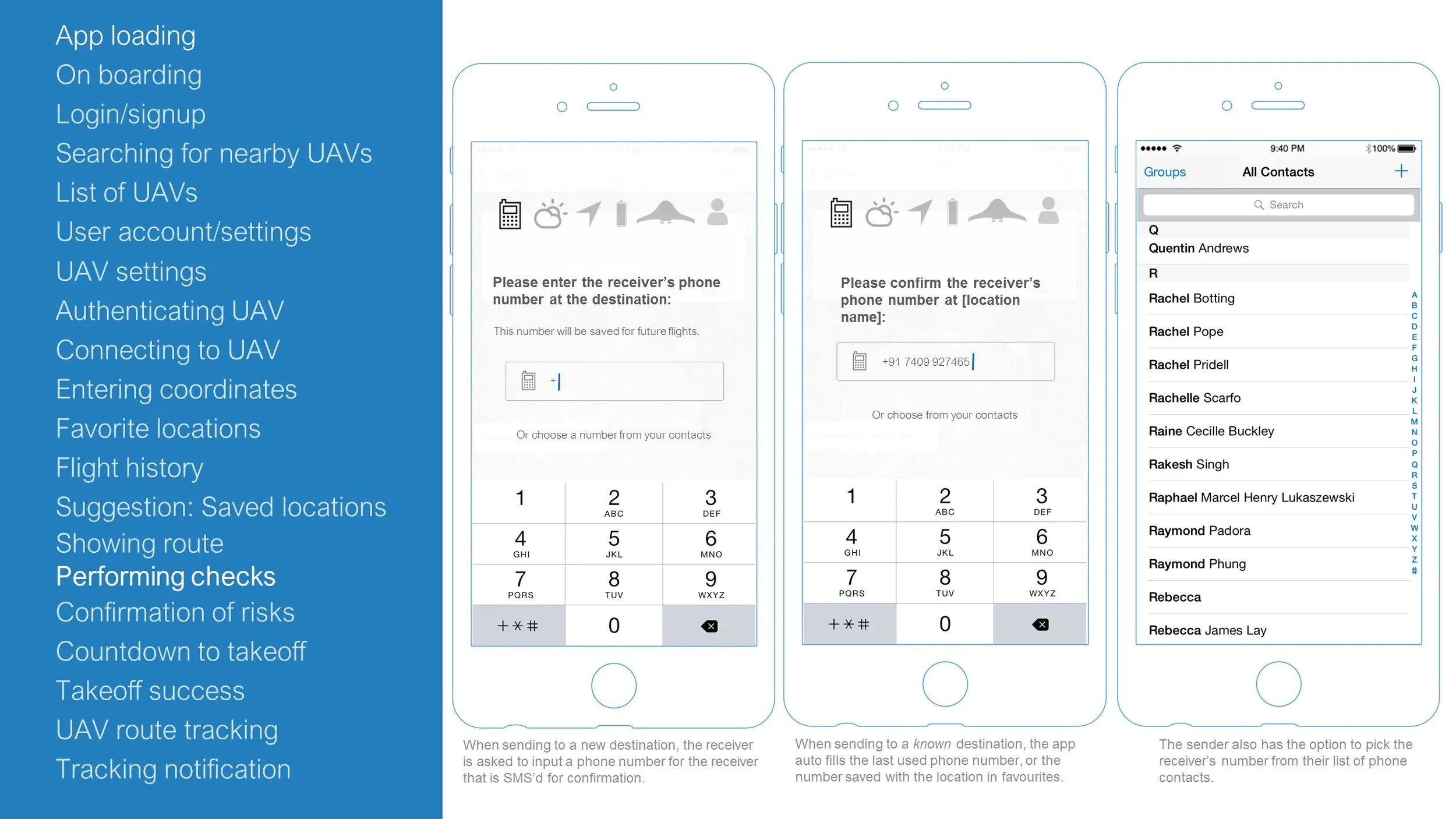

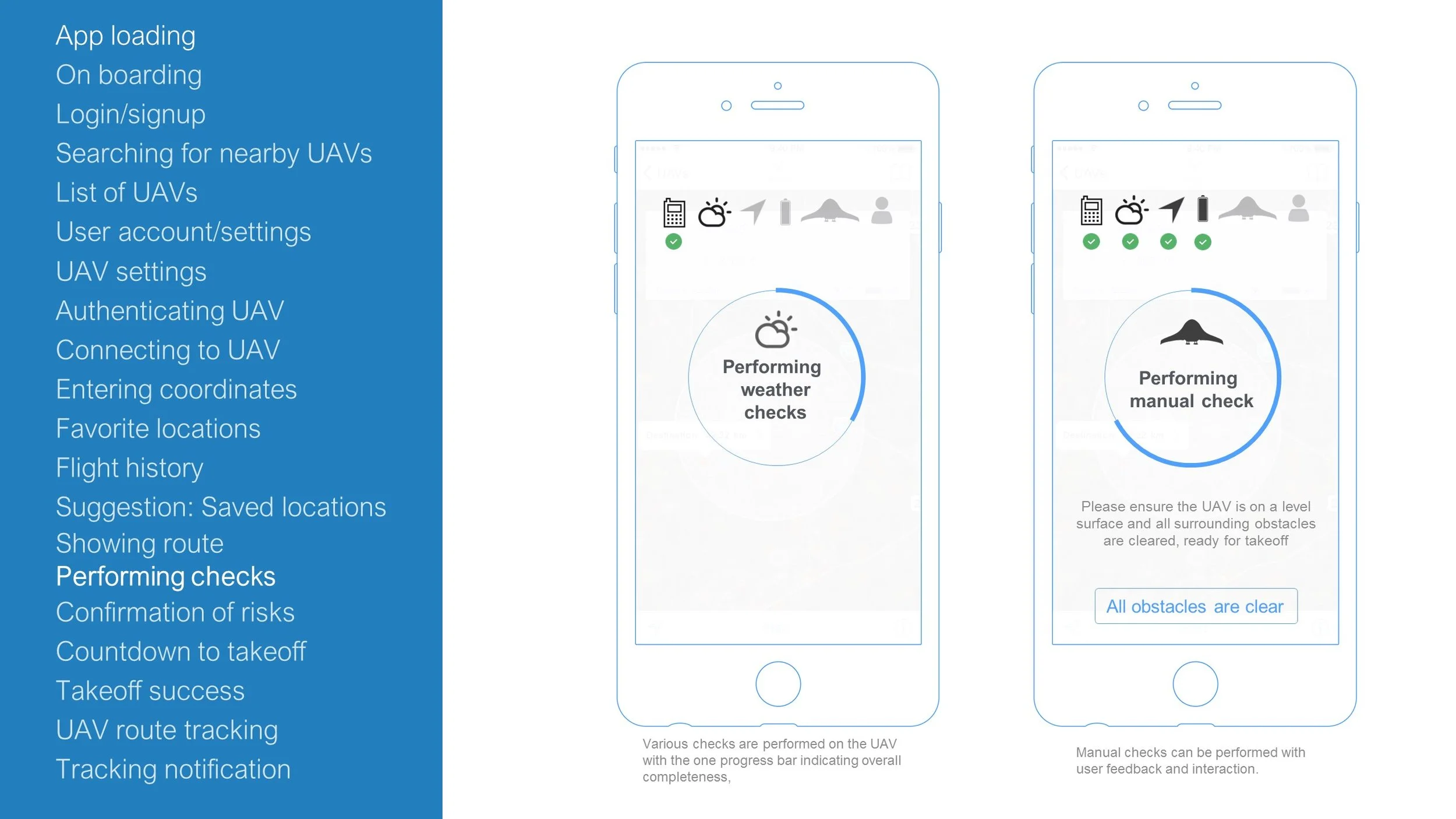

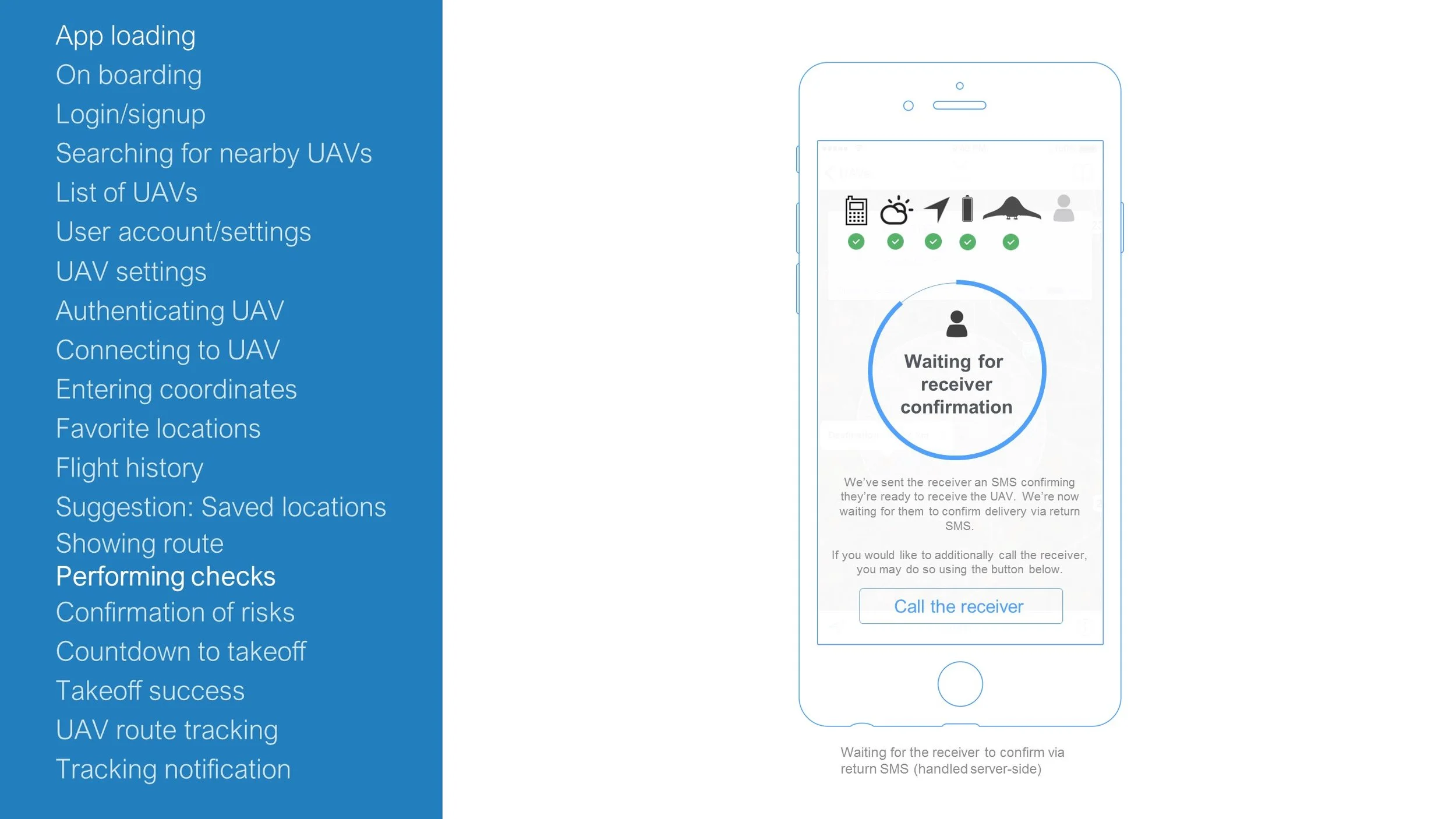

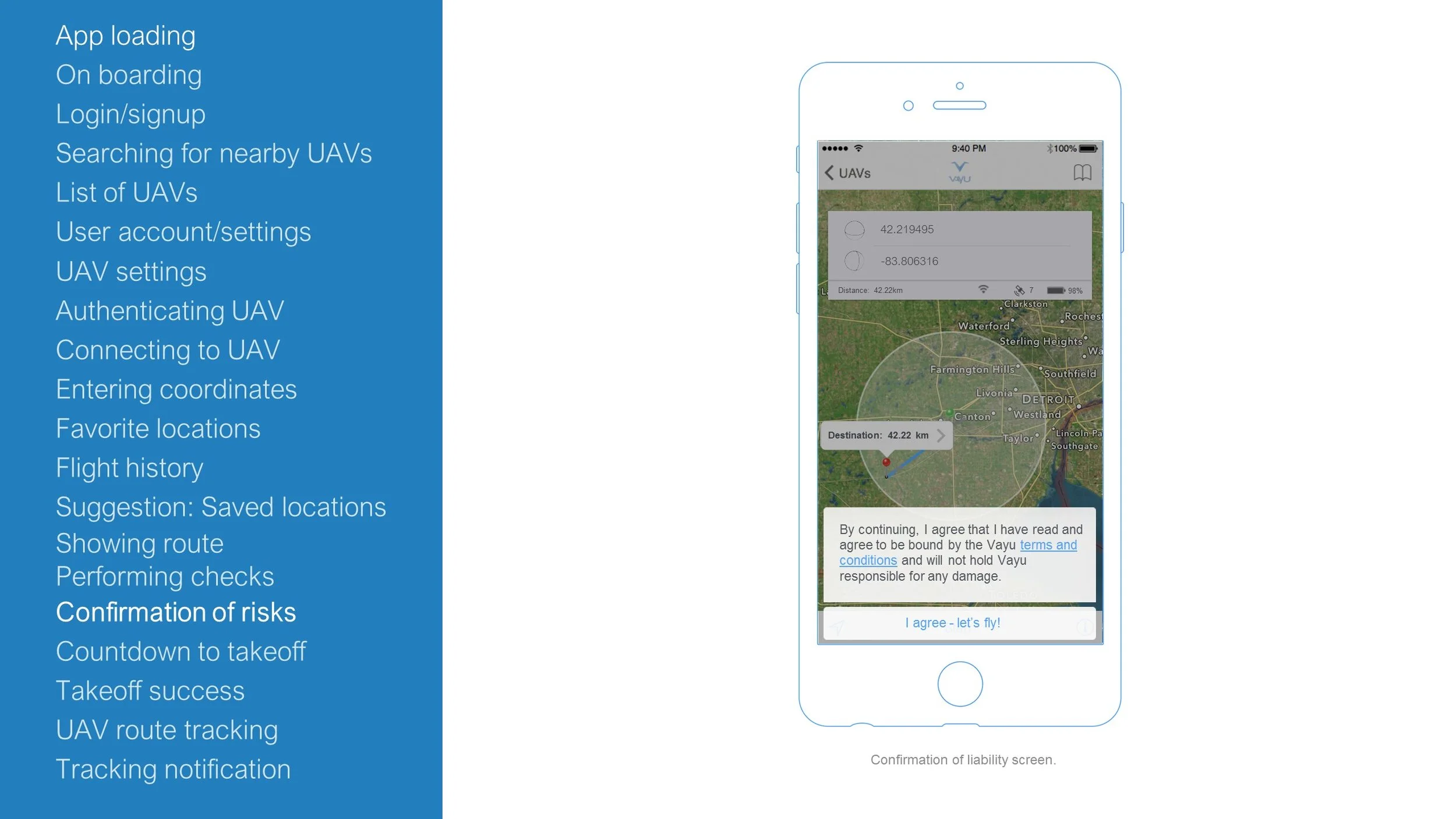

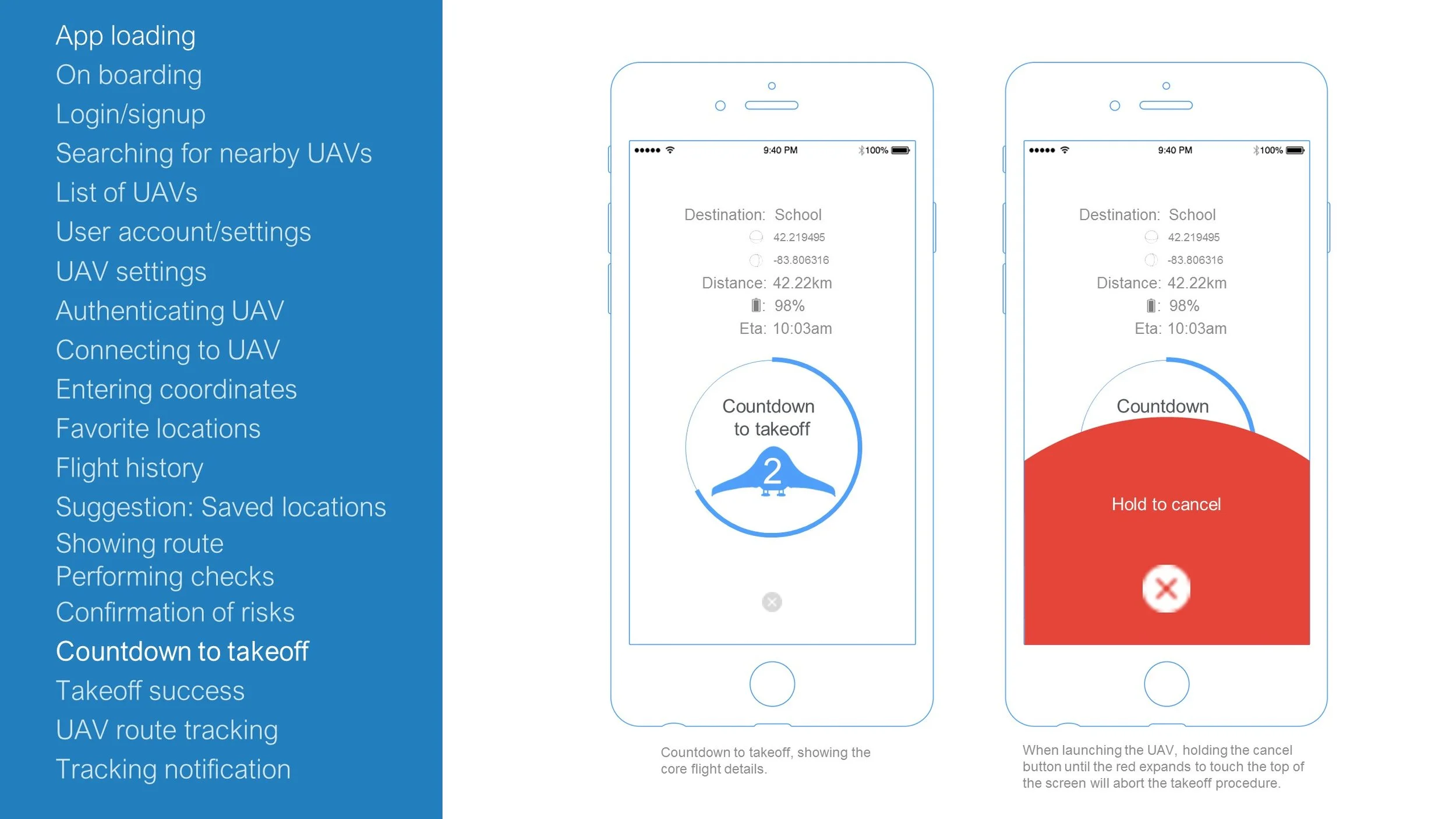

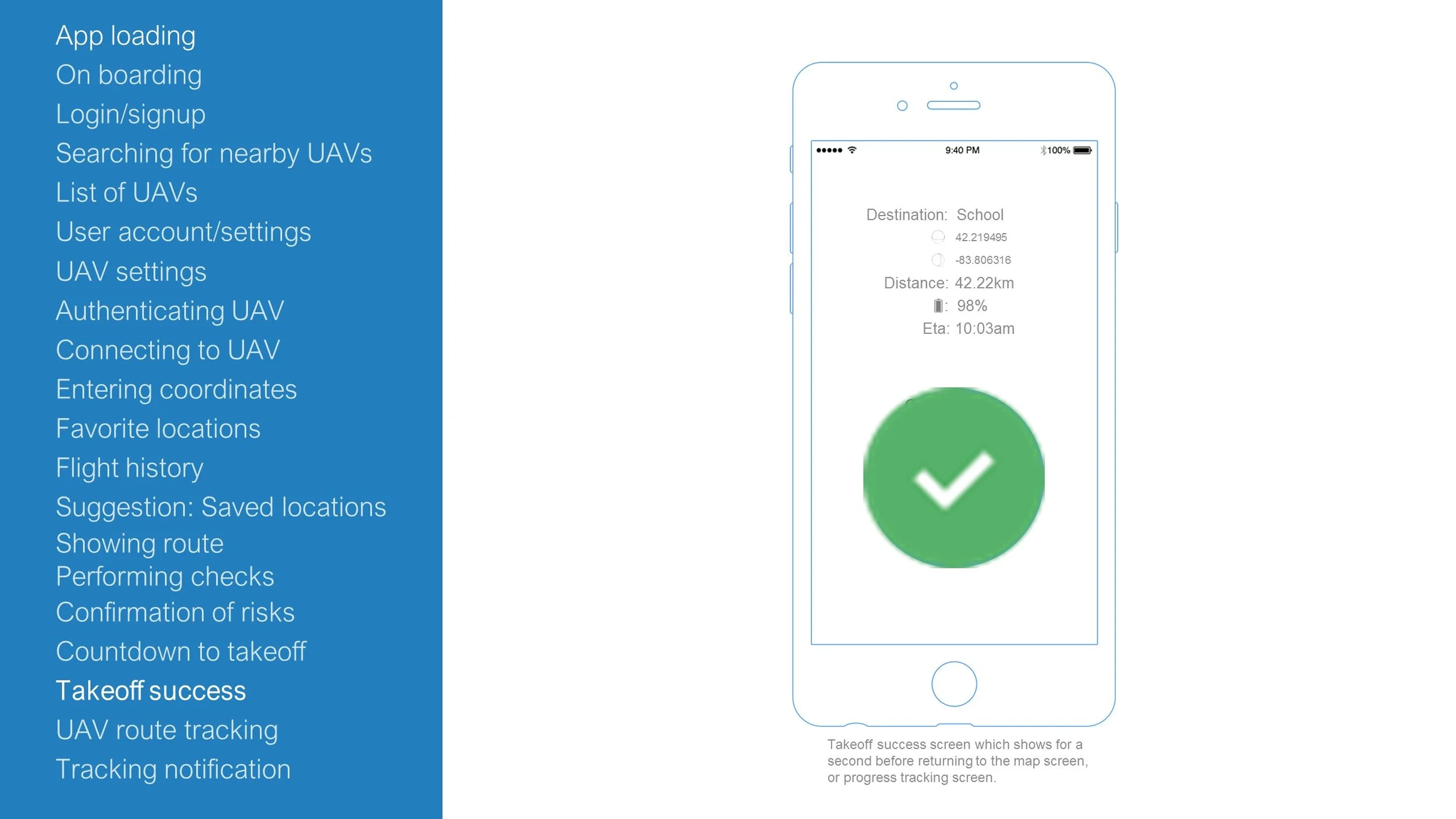

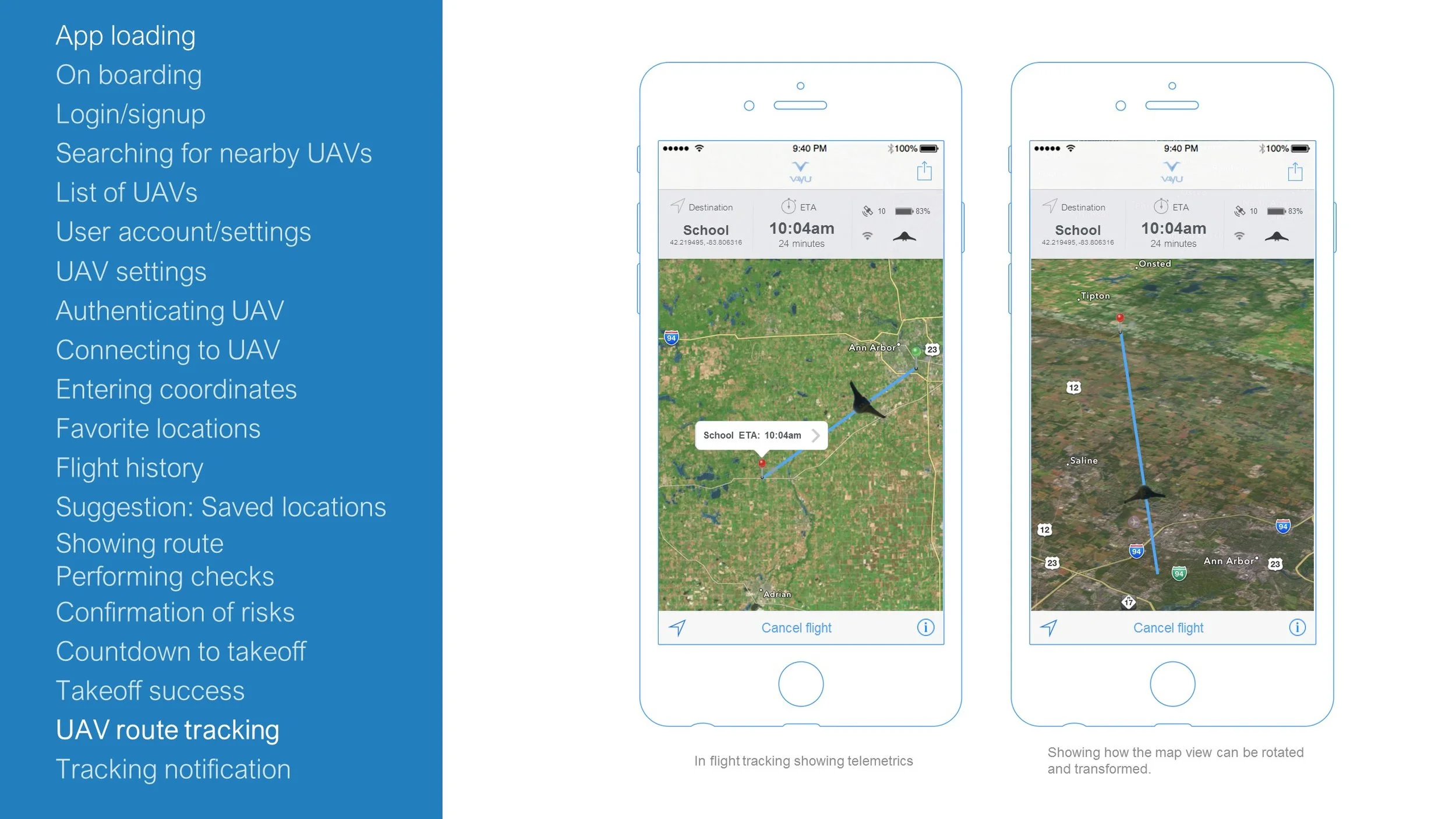

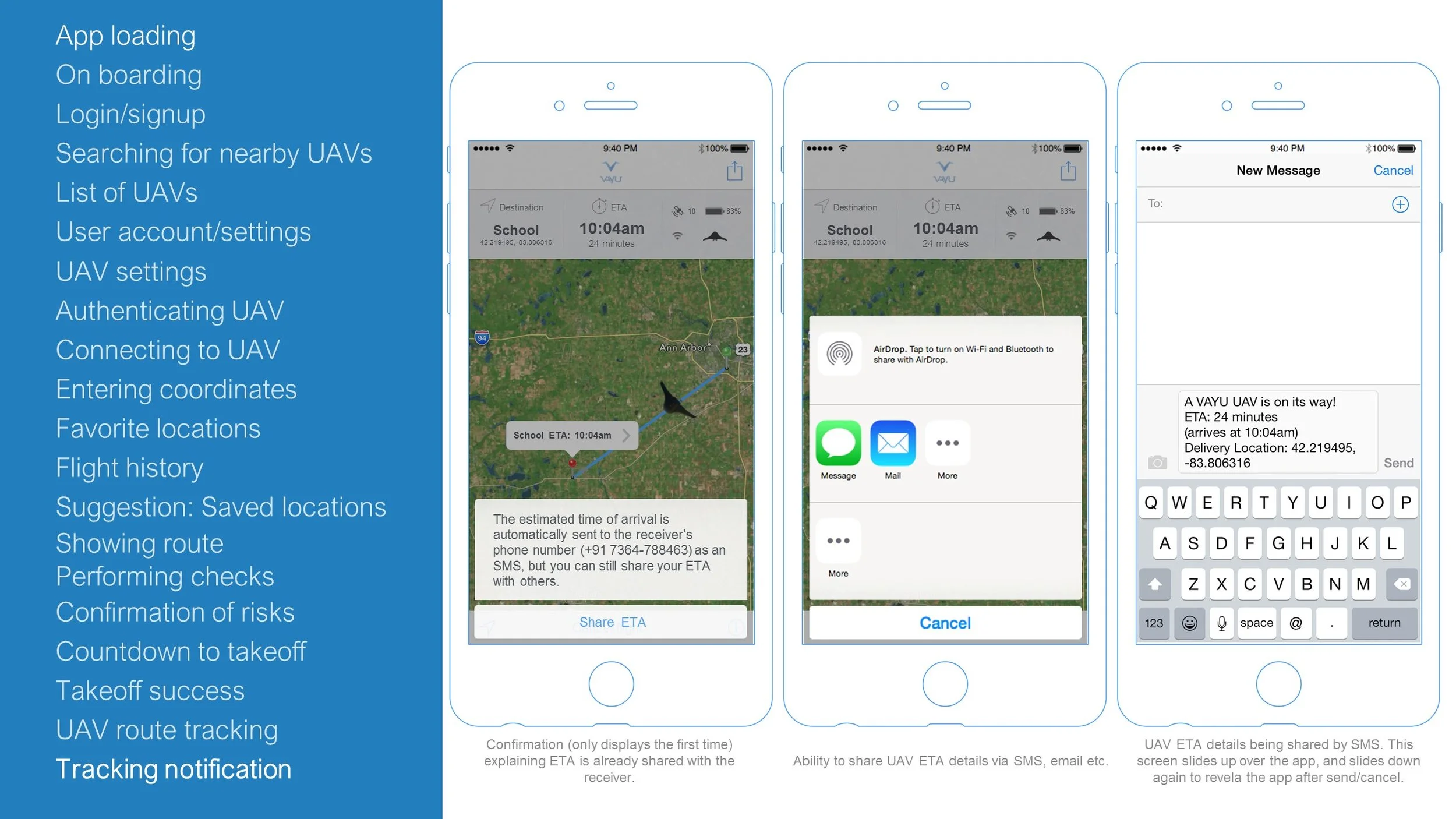

As part our demonstration vehicle, I created simple wireframes and mocks to build a prototype "DISPATCH" application that would allow doctors and nurses to control our drone with little training.

Online Mission Simulator

Even after the new investment/sales deck was complete, the founder and myself continued to spend a great deal of time explaining the use of drones to deliver medical aid.

To bridge this communication gap, I proposed a new way forward; a fully interactive web-based simulator that would allow early customers or investors the ability to simulate delivery of a package – using their own GPS coordinates – from their mobile device.

This would allow anyone using a phone or laptop to send up to 5lbs of 'virtual cargo' anywhere on a Google Maps powered virtual globe.

This simulator would also be a "soft" way to begin exploring the eventual ground control app we would need to build to make the Courier an end-to-end cargo delivery solution. I planned to experiment with design flow, UI visuals, and even gather basic user feedback from the simulator itself.

This was ultimately a great idea, but premature in the company's evolution. The product side was having a difficult time getting the Courier aircraft to work reliably, and I decided to shelve the simulator until we were further in our product development cycle. We continued to use the Investor Deck and videos to illustrate our intent.

The Online Cargo Simulator I designed was to be built around ReactJS, CesiumJS, and the ability to use short URLs and PINs to connect both a mobile device and web browser together in one user session in order to demonstrate how the Courier aircraft would eventually be dispatched from a simple mobile device. To read the full brief click here:

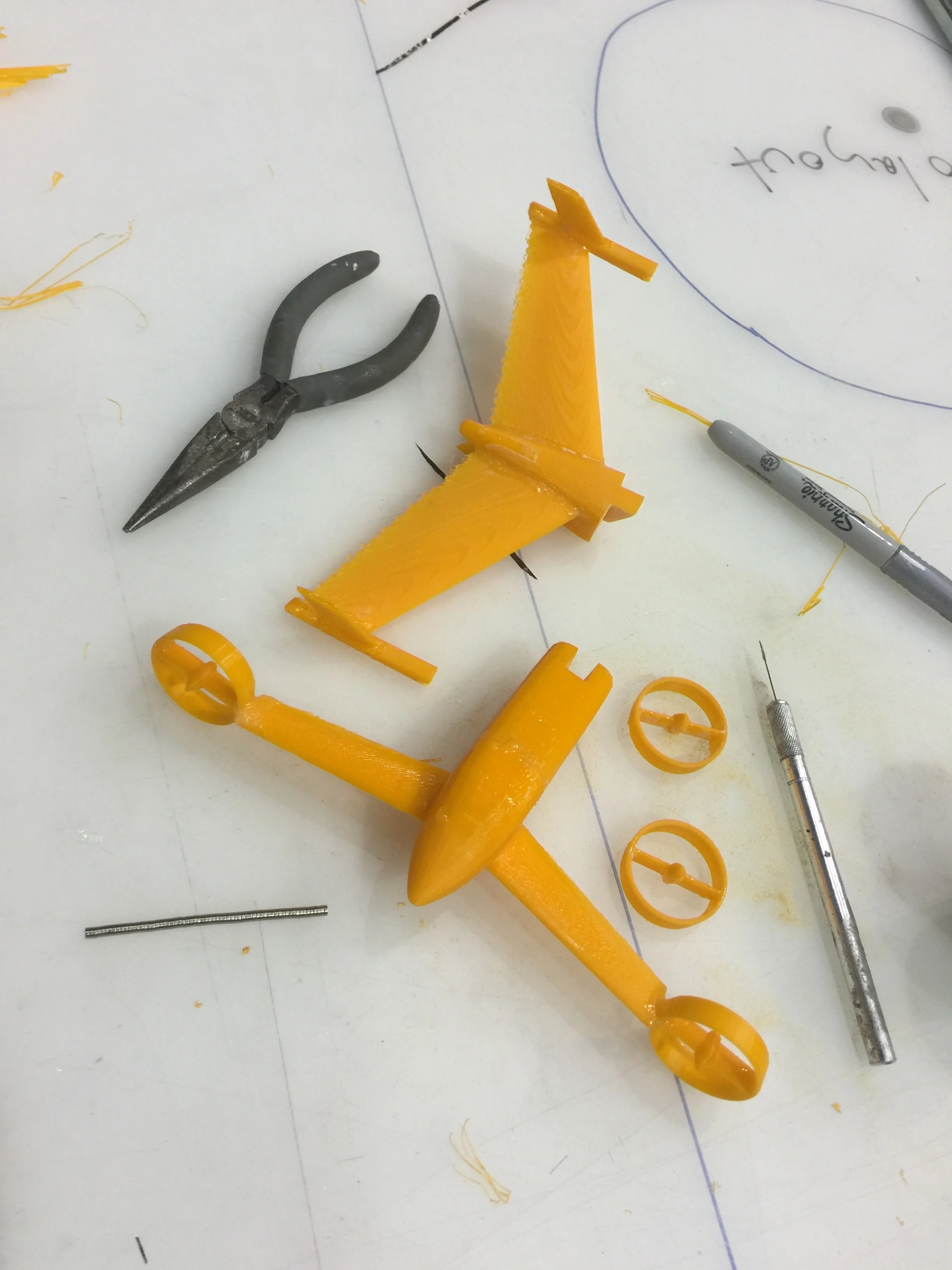

Scale Models

As progress on the P Generation aircraft encountered difficulties, I began working with Vayu's Lead Aircraft Designer to explore other options. We discussed different form factors that would provide similar or better range, easier portability, and a more conventional design that would be easier to control.

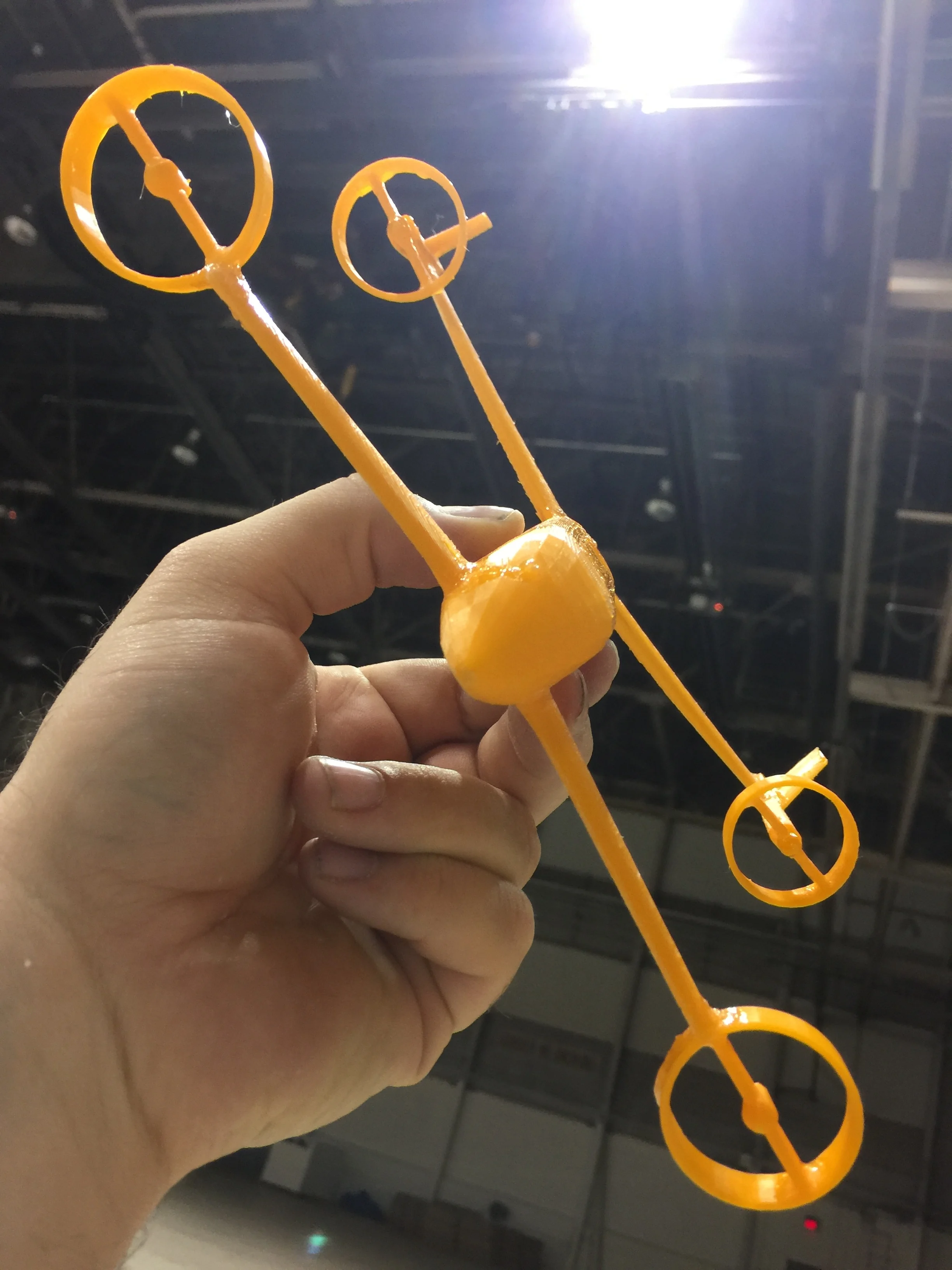

From these explorations in MachUp, I modeled and built small 3D printed models.

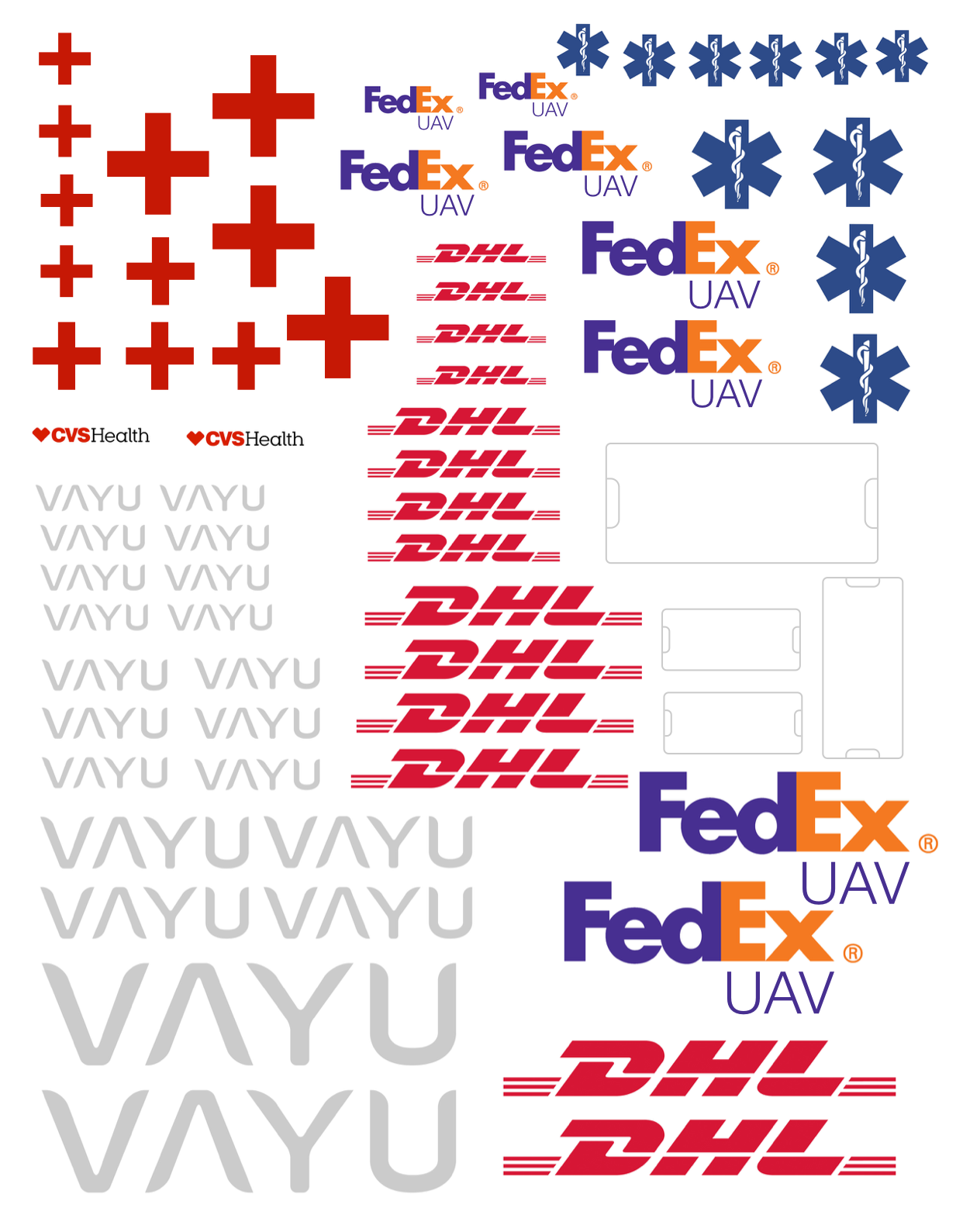

The process for building a scale model from a 3D print is fairly laborious. After a rough part form emerges (overnight), the model had to be fit together, coated with a filler, sanded, primed, taped, painted, and decals applied.

A Turning Point

Toward the end of 2015, I realized there was a problem. The P Generation aircraft was struggling. It had issues with stability in wind, it wasn’t portable, and it’s range data was falling short of the expectations of the market. It was also relatively expensive to make given the capital on hand. Though we had made great progress, “close enough” wasn't going to help kids in Rwanda. There had to be another way forward. That way forward started by asking tough questions.

Having worked closely with engineers, the founder, and our advisers - I posed a pivotal question: Are we building the right aircraft?

Recovering a prototype from the "soft" side of the f

Early concepts I drafted while exploring a new aircraft configuration.

"Product Themes" — Not Features

My first goal was to work with our founder and team to identify the pain points of our customers.

What could they not do today, that they could do tomorrow with our product?

This "customer first" perspective lead us not to a conversation about specific design, but rather "themes" our product should embody in it's eventual form.

The themes we identified:

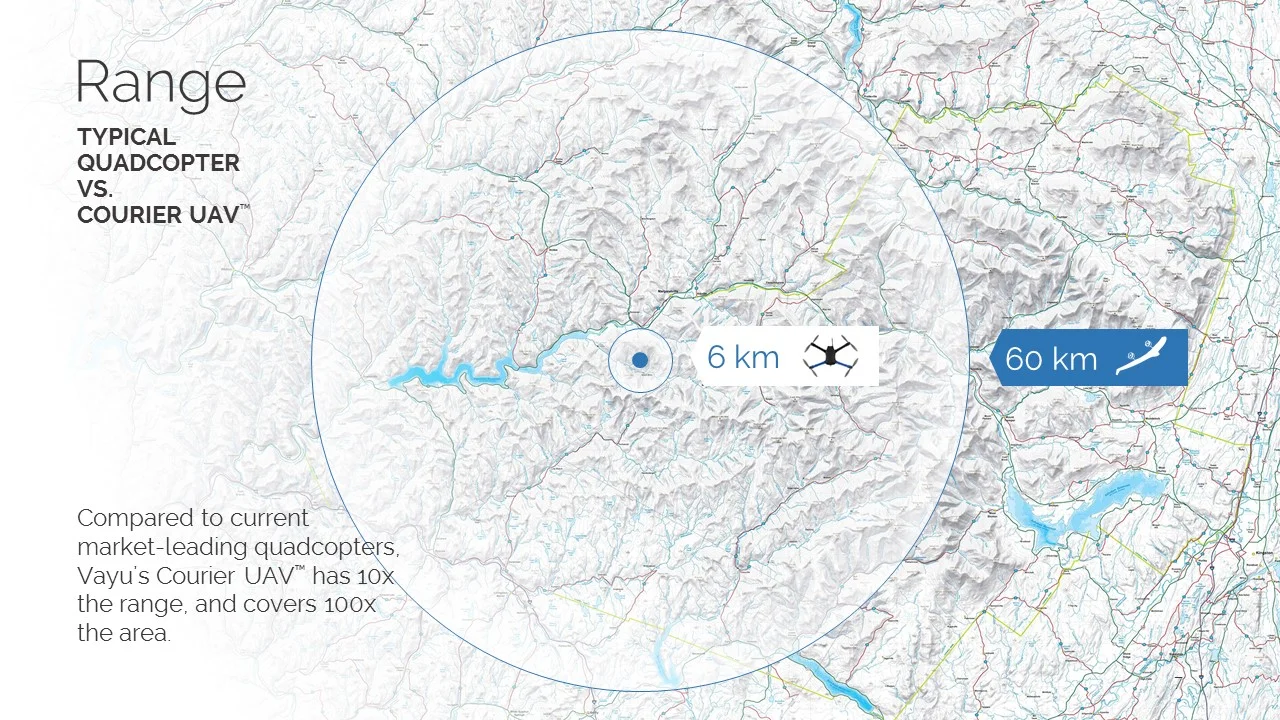

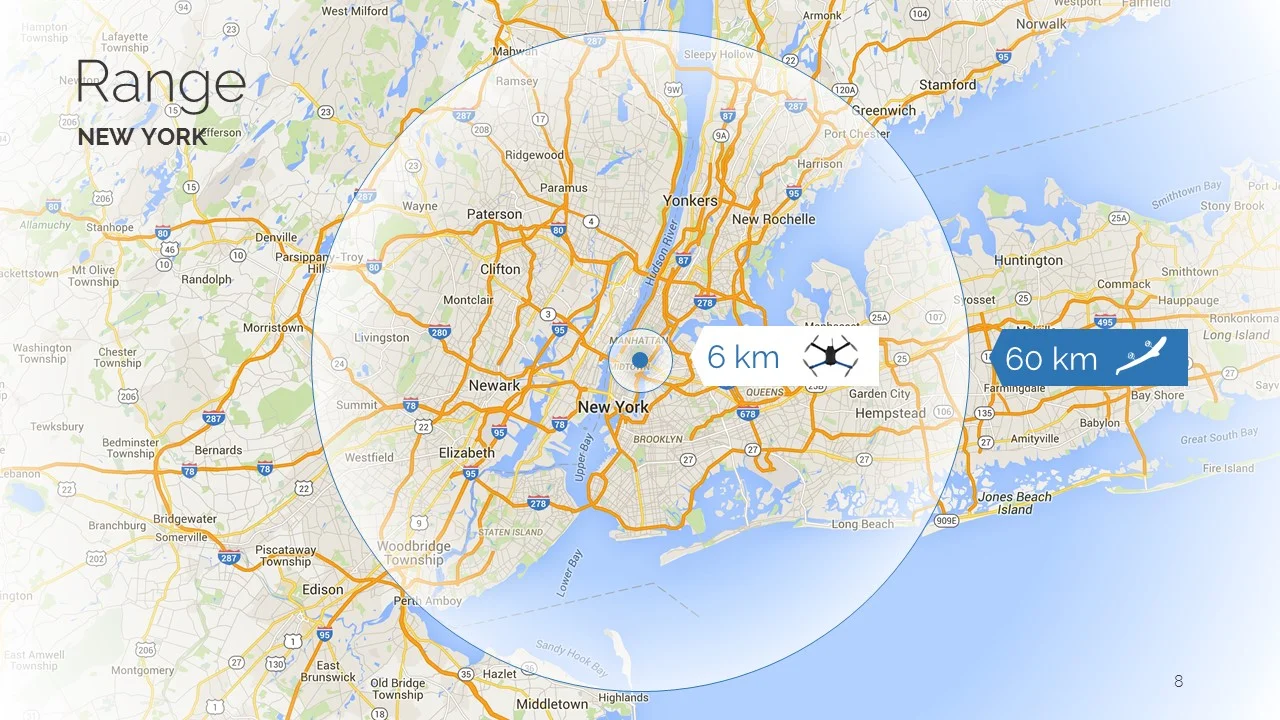

Vertical-Takeoff-Or-Landing (Runways and pneumatic launchers are rare and cumbersome in the developing world.)

Long Range (Quadcopters can serve local populations. What about people beyond the range of quads?)

Cheap (Aid and public health organizations are cash strapped. Having an "accident" with a $70k drone is a non-starter.)

Portable (Situations change dramatically in developing and disaster stricken areas. An aircraft that could be shipped to these places was a must.)

High Capacity Cargo. (5 lbs is enough blood to save a life.)

Easy to Use (Our users are not pilots. They are nurses, doctors, aid workers.)

One of countless brainstorming sessions with the team.

After identifying these themes, I posed harder questions. What are the actual capabilities of our team? How good is our tooling? What are the limits of our financial runway and capital investment?

The P Generation aircraft had reached the limit of it's Margin for Success. The scope of the design was beyond the capabilities of the team, the tooling, and the finances. It's design simply put it beyond the needs of the customer.

Margin for Success = Team + Tools + Capital — Scope Of First Product

From this discussion, I brought up our "Margin for Success." When designing a product with specific themes, how can we create design process where our chance of success is all but guaranteed?

As the leader of our new aircraft, I challenged our team to consider these constraints. Given our mental limits, industrial limits, financial limits — what was the minimum amount of aircraft we could build to satisfy the themes of our customer base?

Minimum Viable Plane

Any great commercial, app, or even aircraft starts from a single place: The brief. Beginning with the themes we had identified as vital to our customers, I worked with the engineers to draft a full product brief that would be the blueprint for all of our design and fabrication work going forward. I also combined the failures of the P Generation aircraft as a reference for prioritizing areas vital to maintaining our Margin for Success. Areas like thrust-to-weight, testing procedures, maximum shipping size, and total cost of manufacture were placed as hard limits in our design process to prevent the snowball effect that can lead to a product that doesn't work.

Early explorations of themes - this aircraft folds into itself.

Unfolded.

Off to save a life.

A New Process

After I completed the Product Brief and received approval from the founder, there were many changes in our design process that I made.

Renewed Focus on Digital Design

On the previous aircraft, some parts of the aircraft were modeled in CAD. Many were not. This led to headaches and excessive hand work when assemblies designed by different engineers were mated.

This changed. All components, assemblies, and COTS parts were fully modeled in a global CAD file.

Anyone could access this file and review. Even masses, part cost, vendor SKUs, and production time were associated as metadata per part.

Exploring configurations virtually.

Early vaccine tube holder I designed in CAD.

Digital Fabrication

Secondly, I pushed the team to focus on digital fabrication. I directed them to explore CNC, Lasercamm, and 3D printing as much as possible while fabricating prototypes.

This focus on computerized craftsmanship was important for two reasons. Many of the engineers were young, and were new to manufacturing aircraft. This led to quality errors that obscured whether the design, or the fabrication were at fault in test failures.

I wanted to be evaluating design intent, not the work of a rookie fabricator. Digital fabrication also allowed us to increase the speed of prototyping.

We were able to reduce the time it took to build a prototype from 18 days, to just 4 days.

CNC-milled vaccine holder.

LaserCAM cut airfoil templates.

Fail Cheap

Finally, I wanted us to save money. I challenged the team to focus on choosing materials that were easy to get, cheap, and easy to machine.

We moved away from costly molds and inconsistent carbon fiber, and towards EPS foam, aircraft plywood, and OTS carbon fiber tube.

LaserCAM cut chassis. The entire chassis is tabbed and glues together like a puzzle.

In the end these process changes allowed us to go from building two prototypes a month, to 5 or 6 WITH design time between. This made a great difference in flight testing. At any time our controls engineers had 2-3 aircraft with them for testing. This allowed us to make dramatic leaps forward on the autopilot and autonomy front, and ultimately validating our design.

People Build Products

Another area of our process that needed improvement had nothing to do with the aircraft. It was about the people building it.

Vayu suffered from rushing ideas and parts into production, while neglecting to do proper design reviews, assign tasks effectively, or manage communication between teams.

Realizing this constant rush was actually slowing down the overall development of the plane, I made several changes.

Cautious not to impose too much process, I began starting each day discussing high level goals for the week with the founder and team. I then guided a discussion where team members could claim tasks that would play to their strengths or interest.

From there, I partnered with a senior engineer to conduct regular design reviews, assembly checklists, DRIs for individual components and processes. This effort was eventually moved to Asana, a product management platform.

This introduction of basic project management took about 6 weeks, but in the end it greatly contributed to the success and speed at which the team brought our product to market.

What gets measured, gets done.

Many Minds, One Pen

As a product manager, my greatest goal was facilitating better design communication between engineers.

As an artist, one of the greatest tools for expressing intent is the pencil. Regularly I would sit with engineers and have them describe parts, processes or concepts to me, and I would draw them.

They would give me immediate feedback on my drawings until what was in their mind, was on my page. This was immensely useful in helping young engineers trained in Excel and CAD communicate their ideas before the detailed work began. This decreased design and fabrication times, and created consistency in the aircraft design. I generated over 500 of these sketches over 3 months.

Early CAD concept I designed from initial sketching. These kind of "North Star" documents help "visualize" early attempts at satisfying a design brief.

Armchair Engineer

From this standpoint I also looked at torsion box style tables from IKEA, and model aircraft. From there I worked with Design Engineer Jemil Ezzet to do a quick materials test using a box structure. The test went well, and we designed and built the chassis from aircraft ply, and finally 1C1 carbon using rules of thumb from shipbuilding

Chassis

After a first attempt at a chassis failed to yield proper torsional stiffness, I dug in to look for other ideas. A few ideas immediately came to mind. In college I had illustrated diagrams for a shipbuilding textbook.

While I didn’t understand the math, I did understand one thing: Structure means strength, not material.

Final chassis design.

Quick CAD concept.

Design iterations of the chassis.

3D printed jig for precision building.

CHassis made from 1C1 carbon fiber. Reduced weight by 60%.

Flying robot.

Disposable Fuselage

In flight testing, of the biggest challenges was recovering from crashes. Though the wings and chassis usually remained unscathed, the foam fuselages we were using were almost always destroyed. They also took 3 days to make in our CNC mill. For this early stage of testing we need to design this component for error, not aerodynamics.

I designed a semi-aerodynamic fuselage that is made completely from cardboard. The fuselages were cut in a large 2D CNC knife cutting machine often used to cut refrigerator boxes.

This method cut production time from 15 hours to 15 minutes, allowing us have more aircraft available for flight tests.

Disposable fuselage made from cardboard.

Fresh off the CNC knife cutter.

Without fuselage.

With fuselage.

Marketing Continues

I produced the following brochure to help not only aid organizations understand the scope of our product, but also aid their communications with local health workers and indigenous communities to understand how our drone could positively impact their health needs.

While serving as product manager for the X Generation aircraft, I still fulfilled duties as Director of Marketing. One of the biggest needs to continue feeding our early sales channel and pilot projects was a physical brochure. In the developing world, printed materials indicate legitimacy.

Cover.

Back page with specifications.

Middle spread.

A Successful Prototype

In May of 2016, our aircraft, the X5C, took off autonomously, transitioned without aid, flew through various preprogrammed waypoints, transitioned out of forward flight, and landed itself without a pilot. Though there is still a long road to go for Vayu, I am extremely proud of this team and our accomplishments. In 5 months we were able to accomplish 90% of the goals outlined in our original design brief, and keep the company on the right track towards helping those in need through robotic aviation.